A closer look at how industrial acoustics and noise control research began at the Institute

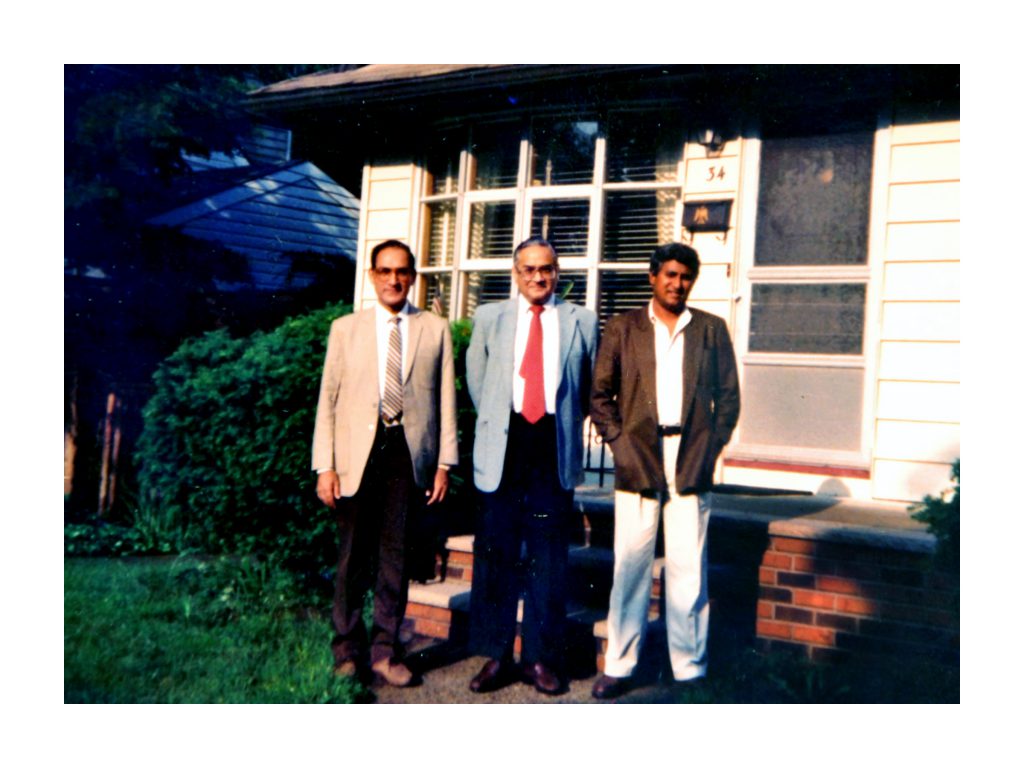

(Photo: KG Haridasan)

In 1896, Henry Ford drove his first experimental automobile down the streets of Detroit in the United States. “My gasoline buggy … was considered something of a nuisance, for it made a racket and scared horses,” he wrote in his autobiography. Soon after, Milton Reeves, another pioneer of the automobile industry, patented a muffler to reduce the noise and fumes emitted by these vehicles. Since then, reducing noise in automobiles has been an important issue that engineers have grappled with. However, this was not the case in India even in the 1970s when the automobile industry was booming.

A few years earlier, in 1968, Manohar Munjal, an ME student in his fourth semester at the Department of Internal Combustion Engineering (which eventually became the Department of Mechanical Engineering) at IISc, was assigned his thesis topic: Analysis and design of exhaust mufflers for automobiles. This was a peculiar situation for him, as the subject had never been part of his syllabus. His friends, worried that this would harm his career, and risk his position as the class topper, urged him to go to the Department Chair and request that he be given a different topic.

But Manohar prided himself on taking up challenges and was not deterred. “After dinner, I went to the library, and in the catalogue, there was a journal called Engineering. In the index, I looked for the keywords ‘muffler’ and ‘silencer’. That’s how I started. During this process, I also came to know that practically nothing had been done on muffler acoustics,” he recalls.

When Manohar looked through the references cited in the papers, he found that the name of one book kept turning up: Fundamentals of Acoustics by Lawrence Kinsler and Austin Frey. Fortunately for him, he found two copies of it in the Department of Electrical Communication Engineering (ECE). “In 15 days, I studied the entire book, solved all the exercises in it, and that is how I taught myself acoustics. But it still didn’t tell me what happens with sound waves travelling in a silencer,” he says.

Manohar came up with general design criteria for silencers, which did not exist back then … this was considered a breakthrough in the field of automobile acoustics

Manohar therefore came up with general design criteria for silencers, which did not exist back then. He developed an algebraic algorithm for describing the acoustics of tubular mufflers using problem solving techniques such as transfer matrix multiplication and mathematical induction, in an age that predated not just computers but also calculators. This was considered a breakthrough in the field of automobile acoustics.

Manohar soon developed a niche for himself in the field. After he graduated, he continued as a lecturer at IISc, and became an Assistant Professor in 1973. Currently an Emeritus Professor, AICTE Distinguished Chair and INSA Honorary Scientist, his work kickstarted research on the acoustics of silencers and ducts in India.

Mufflers

Manohar explains why automobiles and commercial generators need mufflers. “In an engine, the piston is sucking in air and pushing it out very rapidly; this sends out very strong pressure waves into the system, and this produces a lot of noise.” There are two types of mufflers – absorptive and reflective. In the first type, the acoustic waves pass through an absorptive material and lose energy. This energy is converted to heat, resulting in a silencing effect.

The reflective muffler is also known as an impedance mismatch muffler. Impedance refers to the interference in the passage of sound waves due to obstructions or differences in the medium. Most of the sound gets reflected in such situations. “If someone is drowning and I shout, they won’t be able to hear me, as the characteristic impedances of water and air are very different. Sound travels at different speeds in the two media, and there is a strong mismatch,” Manohar adds. Reflective mufflers use this phenomenon by including a series of structures within them that result in multiple impedance mismatches. In such mufflers, some of the sound is reflected back at every step, resulting in a loss of energy and the required dampening of sound.

A joint quest for quietness

One of Manohar’s colleagues at IISc, BS Ramakrishna, a professor at ECE, was renowned for his work on electrical and architectural acoustics. Ramakrishna was like a guardian figure for DN Raju, who in the 1970s and 80s was exploring the uses of vermiculite, a mineral that expands at high temperatures, and could therefore be used as an insulator. One of the goals of his company, Vermiculite India Private Limited, was to investigate the mineral’s applications in industrial noise and heat control. Ramakrishna put Manohar in touch with Raju. “That was how our association began – to see if vermiculite could be used in silencers,” says Raju, whose work impressed Manohar. “Raju was very creative and gave shape to our ideas. I was a theoretician, and once I told him what I needed, he would come back in some time with beautiful sketches for fabrication,” Manohar says. Having grown up on campus, under Ramakrishna’s wing, Raju explains that he has been exposed to acoustics since he was a toddler. “From the first meeting itself, we [Manohar and I] worked on the same wavelength,” he adds.

During the 1990s, when Manohar was a member of the Science and Engineering Research Council (SERC) at the Government of India’s Department of Science and Technology (DST), he gave a talk about quieter technologies and the importance of acoustics in engineering and machine design. This was an eye-opener for DST, and they sanctioned Rs 1.25 crore to set up a Centre for Excellence in Technical Acoustics at IISc. They had one condition though – a minimum of 15% of the total cost should come from industry. And so, the Facility for Research in Technical Acoustics (FRITA) was born, in collaboration with Raju as the industry partner. “We needed a model for FRITA. With my own money, I travelled with Prof Munjal to dozens of acoustic labs all over the world. Without copying a single thing, we designed our own set-up,” he adds. In June 2000, Raju’s company, Noise and Heat Control Systems Private Limited, entered into a renewable, 15 year joint venture contract with IISc and FRITA, to work on projects dealing with industrial noise control. “This association led to a lot of indigenisation of technology, at a time when many heavy industries like automotives were dependent on know-how from abroad at exorbitant costs,” adds Raju.

One of the landmark projects that they worked on together was with Tata Motors. “It was the first of its kind for the country to make a large anechoic chamber where even a truck could enter. The chamber was fully designed by FRITA, and the acoustic wedges required for it were also designed and tested at the FRITA facility. It was made fire-proof using vermiculite based coating, and is in use even to this day at Tata Motors,” says Raju. Anechoic

chambers are experimental rooms where sound cannot escape, and external noise cannot come in. This allows for accurate measurements of the acoustics of any device. Most anechoic chambers are made by installing a thick layer of an absorptive material like glass wool, mineral wool, ceramic wool or a special sponge-like material known as acoustic foam. Raju and his company have since designed and installed several such chambers for various departments at IISc.

Another memorable project was with the Central Pollution Control Board (CPCB). In the 1980s and 90s, diesel generators were commonly used in commercial establishments as there were frequent power cuts. But these generators were very noisy and produced a lot of fumes, and the onus to find a solution to these issues was on the user. In 2001, CPCB contacted IISc to find a permanent solution to this problem. After many iterations, Manohar and Raju made a novel prototype of a generic acoustic enclosure for generators that did not affect the wattage, had ventilation for the combustion, and also reduced the noise. It took them almost one-and-a-half years to convince genset manufacturers – including big names such as Birla Yamaha, Honda and Ashok Leyland – to adopt the technology. Raju recounts, “Finally, one day, before a meeting called by the CPCB and in the presence of government and industry representatives, we switched on the generator with our enclosure design. After the meeting was over, they said, ‘Okay, let’s start the generator and see if it works.’ We told them that all this time it has been sitting next door and has been working! The impact on the others in the meeting remains unknown, but the CPCB representative was duly impressed.” The report that the representative submitted to the government eventually led to new noise limits being set for gensets, and made the use of acoustic enclosures mandatory for the manufacturers of all diesel generators.

Silencers under the sea

Manohar’s algorithms for the design of mufflers have had other applications too. One of these was in reducing breakout noise through ducts, such as those in air conditioning and ventilation systems. Over the years, he has been teaching architects about breakout noise through these ducts, and how it can be used for industrial snooping.

When the Indian Navy was looking for ways to reduce the sound of underwater propellers, so that it couldn’t be picked up by enemy sonar, they contacted Manohar through Ramakrishna. In collaboration with former ME faculty member Vijay Arakeri, Manohar worked on the noise characteristics of marine propellers and self-noise of underwater bodies. Later, Manohar was asked to work on acoustic propagation across lined hulls. “I did not know anything about submarines or underwater acoustics,” he recounts. But he took up this challenge too, and developed indigenous and cost-effective stealth linings for submarines that could absorb the sonar pings of enemy ships. “Visible light and electromagnetic waves cannot move far underwater. Detection and stealth under the sea is all through the

use of acoustic waves. In association with my research student Satya Narayana Panigrahi, I was able to do some pioneering work in this field for the country.”

(Photo courtesy: Manohar Munjal)

Noise control

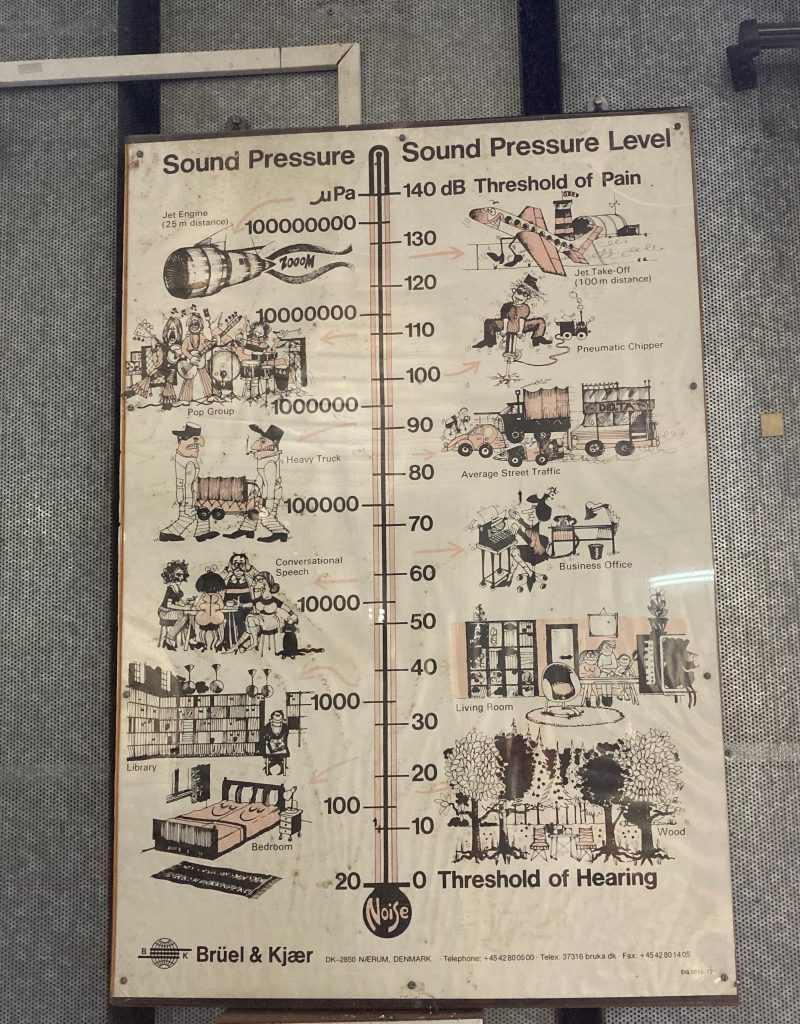

Noise is measured as the sound pressure level in decibels (dB). The relative loudness of sounds in the air as perceived by the human ear is expressed as A-weighted decibels or dBA. Normal human speech is typically around 55 to 60 dBA – a shout is 75 to 80 dBA – while the sound from an automobile without a silencer is 120 dBA. “At 130 to 135 dBA, you will feel as if someone is piercing a needle through your ear, and 155 dBA can render you permanently deaf,” says Manohar. He describes their very first project in noise control, in response to an enquiry by the Fertiliser Corporation of India’s branch in Sindri, in erstwhile Bihar. The plant used air at very high pressures for the chemical reactions to make fertilisers. The noise when this air was released through the exhaust vent was unbearable, enough to damage the ear drums. Even though these vents were placed at a height of 20 metres, the din was still too much. “When we went there, we found that there was not a single bird in the entire area. They had either died or flown away. That day, I realised how our human actions can be so cruel, knowingly or unknowingly, to the creatures around us.” Manohar’s silencer designs, which brought about a reduction of 50-55 dB in the noise generated, are being used by those factories even today.

There are other ways in which sound waves can affect living beings. Human ears can hear sounds at frequencies between 20 to 20,000 Hertz (Hz). “At frequencies lower than 20 Hz, known as infrasound, I may not be able to hear anything, but my body can feel it. The resonant frequencies of my chest, arms and thighs are around 6 to 8 Hz,” explains Manohar. He

recalls a scary incident when he was a consultant to the National Aeronautics Laboratory (NAL). On entering the control room of a wind tunnel, he felt as if he had been kicked in the chest, and somehow made

it out before he collapsed. He was wearing earmuffs, and realised only later on what had happened. “There was peak noise at 8 Hz, so I couldn’t hear it, but it affected my body.” Similarly, animals such as bats that can pick up ultrasound over 20,000 Hz might be affected by machine-generated noise that is beyond human hearing.

(Photo: KG Haridasan)

As the long-term Chair of the National Committee for Noise Pollution Control, Manohar was also instrumental in setting up guidelines for the noise limits that vehicles can produce. Any new vehicle that produces a pass-by noise of more than 74 dB cannot get a road-worthiness certificate. Ironically, Manohar has also been involved in the resolution of Public Interest Litigations (PILs) against noise created by tampered silencers. “The slightest damage to reflective or impedance mismatch silencers results in it making more noise than before. These days, after buying a new vehicle, just for a kick, some people go to unscrupulous mechanics who will make one or two holes in the silencer at the ‘right’ places, and the result will be like an ‘anti-baansuri’ [anti-flute]!” says Manohar. After several complaints were made to the National Green Tribunal about these deliberately tampered silencers, and other sources of noise like loud pneumatic horns, the Karnataka State Pollution Control Board was called upon to respond, and Manohar was once again roped in as the expert. Also in attendance were the Bangalore Development Authority, the Bruhat Bengaluru Mahanagara Palike and other public agencies. A report based on these discussions was released in July 2021.

Challenges

It hasn’t always been an easy road for Manohar and Raju. “For India, noise was celebratory. For a country which says ‘Horn, OK please’, any function which is quiet is not a successful one,” says Raju. Getting people to take noise control seriously was a challenge, especially in the early years. Raju recalls an instance when they went to a sheet metal shop. “The manager sat peacefully amidst the continuous din of metal being pounded. When he was asked how he could work in the noise, he said, ‘Sir, if we don’t hear that, our heart fails, because the noise is money for us. It means that production is going on.’ He couldn’t fathom the fact that there could be a way to see the work happening, and block out the noise as well.”

Manohar also had similar experiences. Once, Kirloskar Oil Engines Limited had asked his team to design a new muffler. Later, when Manohar met their Chief Engineer at a conference, and asked him how the new mufflers were performing, the latter couldn’t recall their design. “When I said it was 7 dB quieter than the others, he remembered and said that they couldn’t use our mufflers as they were 8 annas costlier than others,” says Manohar. “Noise reduction was absolutely immaterial … insignificant at that time.”

Things, however, have come a long way since then, and acoustics and noise control are now held in high esteem by the industry. “Reduction in noise means longer-lasting and better machines. Other benefits [of quieter technologies] on the quality of life and on aural health are perhaps not as tangible, but equally important. Prof Munjal took it upon himself to go to

every industry and talk to their engineers,” says Raju. “We must have reduced thousands and thousands of dB together, for the country.”

For more stories on the Department of Mechanical Engineering, please click on the links below:

Making Things Work: 75 Years of Mechanical Engineering

Remembering Arcot Ramachandran