A glimpse into the origins and evolution of product design at IISc

(Photo courtesy: Sickle Innovations)

In a cotton field in Gujarat, the pickers have a delicate and labour-intensive task before them. That task is now less tiresome than earlier because they are trying out a light-weight, battery-powered device which makes their job faster and easier. These are prototypes of a cotton picking machine designed by Sickle Innovations, a farming solutions company co-founded by IISc alumni. It is projects like these that bring out the entrepreneur in a student, as they step into a realm full of innovation and enterprise – product design. A key requirement for creating such impactful innovations is an environment that incubates and encourages out-of-the-box thinking. Which is exactly what the Department of Mechanical Engineering (ME) at IISc has been providing for the last 75 years – long before terms like ‘innovation incubator’ were in vogue. The Department has pioneered teaching and research in design way ahead of its time, and also contributed to developing other related interdisciplinary centres at IISc.

Sowing the seeds

The ME Department offers one of the longest running courses in design, called Design of Engineering Systems, which was initiated back in 1963 by MR Raghavan (who retired from IISc in 1988). The course has continued in one form or the other over the years. Today, it is being offered as Creative Engineering Design by Amaresh Chakrabarti (Professor and Chair of the Centre for Product Design and Manufacturing or CPDM), himself an alumnus of ME. One of Raghavan’s students was TS Mruthyunjaya, who joined the Master’s programme at ME when only two faculty members were working on design research – MR Raghavan and P Srinivasan. Within a few years, he became part of a growing pool of faculty researchers in ME, dabbling in the field of Mechanisms, which is the study of the construction of devices that rely on mechanical movements to perform their functions. Mruthyunjaya, who first taught the subject at ME, says, “[The] ME Department in IISc became a centre of research activity in India in the field of Mechanisms.” This tradition is now being continued by his own student, Dibakar Sen, who is now a professor at CPDM and ME, and teaches a course on Mechanism Design. Mruthyunjaya laughs while remembering his first time teaching the subject, saying that he was “very, very disappointed” with his performance as a teacher, and that it motivated him to delve deeper and sparked a life-long career in the subject.

Over the years, the ME design community kept assimilating expertise across subjects and backgrounds. In the early 1970s, LS Srinath came from IIT Kanpur and strengthened the Department’s research in Solid Mechanics. With the merger of the Department of Internal Combustion Engineering (ICE) with ME in 1971, areas like noise control and acoustics, nurtured by faculty member Manohar Munjal, began to influence design research in ME.

“The best products of the department are the students themselves.”

At the turn of the century, newer research areas were developed by B Gurumoorthy, R Narasimhan, Ashitava Ghosal and others. They established groups specialising in Computer Aided Design (CAD), Finite Element Analysis (FEA), and nanotechnology and robotics, which are the core strengths of design research anywhere in the world. Their labs continue to

attract student talent to IISc. As Gurumoorthy says, “The best products of the department are the students themselves.”

Setting up of CPDM

ME has been a nursery for several interdisciplinary centers in IISc, one of them being CPDM. Mruthyunjaya was instrumental in its establishment. He recounts how he became deeply interested in creative engineering design through the lectures of Bernard Roth, a visiting professor from Stanford University, in 1984. A couple of years later, during his sabbatical as Visiting Professor at Ohio State University, he utilised the opportunity to study design methodology in depth and eventually took over the ME Department’s engineering design course in 1988. A final push towards the creation of CPDM came during the ME Department’s golden jubilee year in 1995 when it was hosting the International Conference on Advances in Mechanical Engineering (ICAME). In a panel discussion, Mruthyunjaya realised the potential of a programme exclusively tailored for studying product design. With inputs from colleagues at the Centre for Electronics Design and Technology (CEDT, now known as the Department of Electronic Systems Engineering), a Master’s programme in product design was launched in 1997. A year later, this led to the formation of CPDM, which is one of IISc’s most sought-after departments today.

“I envisioned CPDM as a unit where we can train students from diverse backgrounds … because uniformity is not good for creative efforts”

“I envisioned CPDM as a unit where we can train students from diverse backgrounds … because uniformity is not good for creative efforts,” says Mruthyunjaya. He led the centre from 1998 till his retirement in 2003, with a vision to combine engineering and industrial design and make products that balance functionality, usability and aesthetics – a need that was not being met at any premier institute in India. Gurumoorthy also credits the interdisciplinary nature of the centre to giving an impetus to students’ creativity. CPDM continues to be true to its mission, with faculty members’ and students’ backgrounds ranging from architecture to metallurgy. “Mechanical Engineering can be justifiably proud of its offshoot – CPDM,” Mruthyunjaya adds.

Real world applications

Taking their expertise to the field has been a long-standing practice at the ME Department. In this regard, former faculty member S Soundranayagam’s contributions to turbomachinery are hailed by many, including Abdul Kareem A, a technical assistant who joined the Department 38 years ago. Abdul remembers their efforts to set up a mini hydroelectric power plant in a village in Mandya district, working with the Karnataka Power Corporation Limited (KPCL), and also their visit to Vishakhapatnam where they worked on torpedo propeller designs for the Naval Science and Technology Laboratory (NSTL).

In recent years, students of ME and CPDM have put their creative minds to focus on issues of agriculture, mobility and healthcare. These choices are a “testament to the students themselves,” as Gurumoorthy puts it. “Students were not so keen on designing lifestyle products; they were more keen on solving problems of the people around us.”

One of the labs working on design optimisation with a focus on biomedical devices is that of GK Ananthasuresh, who was the Chair of ME until recently. His students have developed compliant mechanisms that enable the study of the mechanical properties of cells. Compliant mechanisms are joint-less, flexible structures that can transmit forces. This technology is being commercialised by a Bangalore-based startup, BendFlex, founded by the lab’s alumni. Virtual reality-based products from the lab have led to the establishment of another startup – Mimyk. His students are also collaborating with geriatric specialists to design comfortable and adaptable seating solutions for the elderly.

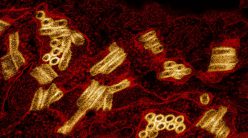

Biomedical devices are also the focus of the Applied Geometry and Mechanisms lab led by Dibakar Sen, where students work on prosthetic limbs, among other areas. One of their projects led to the founding of a company called Grasp Bionics, which is pushing boundaries in rehabilitating amputees. Another product designed here is a chair to make the dialysis process more comfortable for patients.

At the lab run by Ashitava Ghosal, another faculty member at ME, robotics technology is being applied to design tools that help surgeons perform minimally invasive surgeries. Manish Arora, a faculty member at CPDM heads the Universal Technology Solutions for Accessible and Affordable Healthcare (UTSAAH) laboratory, where the focus is primarily on providing efficient design solutions to make healthcare universal and accessible. Their projects range from developing better insulin pumps to rehabilitation solutions for children who are hearing impaired.

To bring these ideas to life, the ME department has continuously fostered collaboration between academia and industry. When computers became essential for designers but were still prohibitively expensive, ME started a one-of-a-kind design service for the industry where the expertise and computing resources of the ME research groups would be available to solve practical issues faced by the industry. Udipi Shrinivasa, who retired from ME as a professor in 2012, recounts how novel this scheme was back then. “People laughed at us,” he says. But they went ahead and collaborated with Tata Consultancy Services (TCS) to develop the Advanced Product Design and Prototyping (APDAP) initiative. In 1995, rapid prototyping was introduced to produce quick and efficient prototypes for companies that would usually have to wait for several months for their designs to be manufactured abroad. The success of APDAP triggered engagement with Micro and Small Medium Enterprises (MSMEs), which eventually led to the birth of the Society for Innovation and Development (SID), currently headed by Gurumoorthy. “What SID has brought to the table is the comfort with which faculty can engage with the industry,” he says. SID not only acts as a bridge between industry and researchers, but also incubates startups, a few of which are founded by alumni from ME and CPDM.

Future directions

With its diverse expertise in biomedical systems, ME is uniquely poised to contribute to this field. Future directions also include generative design – through which optimised design solutions can be generated on a computer and then fine-tuned by the user. Foundational work in this field is already being done by Gurumoorthy, Ananthasuresh and others. Another exciting area is the design of next-generation materials, such as those for building structures in space, which is being investigated by Aloke Kumar, a faculty member at ME. Taking inspiration from nature, his lab is experimenting with a special class of materials called ‘soft matter’. Another group adapting design principles from nature is the Biomechanics Lab run by Namrata Gundiah, also a faculty member at ME.

Balancing these technological advances is the emerging spotlight on sustainability. With increasing consciousness about sustainable design, it is only a matter of time before the designers at IISc make it the focus of their products. These ideas have already begun to take shape, as is visible within the ME Department building itself. In 2013, a new auditorium was inaugurated. It does not have a gleaming exterior or a swanky interior, not even air conditioning. It doesn’t need to, since the design makes the most of its surroundings and the mild Bangalore weather. Strategically placed windows and ventilation keep it comfortable, while specially selected and locally crafted wall tiles give it the best acoustic experience. It is engineered to maximise functionality and usability while minimising maintenance.

The design of the auditorium is a reflection of the inward-outward balance that the Department has achieved over the years. While their products are at the cutting edge of technology, they are grounded in context, application and relevance – whether it is the turbine designs of the eighties, or the biomedical devices of today.

With input from Connect staff

Sidrat Tasawoor Kanth is a PhD student at the IISc Mathematics Initiative (IMI) and a science writing intern at the Office of Communications

For more stories on the Department of Mechanical Engineering, please click on the links below:

Making Things Work: 75 Years of Mechanical Engineering

Remembering Arcot Ramachandran