How ME research aims to make a difference in clean energy, manufacturing, healthcare and more

JN Tata, IISc’s founder, strongly believed that scientific research played a role in social and economic transformation. The Department of Mechanical Engineering (ME), one of the largest in IISc and currently celebrating its 75th year, has had a history of conducting research aimed at having an impact on industry and society, a tradition that continues today.

A particular focus has been on translating technology in the area of energy. According to a souvenir published during the Department’s Golden Jubilee, the turbomachines group at ME pioneered the design of microhydel power generators, which were used to power coffee estates in Coorg and small townships in Kedarnath and Arunachal Pradesh. In collaboration with the Department of Electrical Engineering, former ME faculty member S Soundranayagam and his team developed a prototype for low-cost microhydel crossflow turbines that could exploit energy from small drops in height at irrigation canals. In a DST-funded project in Nagaland, he and his team trained personnel in the use, design and installation of these turbines. Based on his design, the Science and Technology Council of Nagaland has funded the installation of two additional projects that have the potential to meet the energy demands of several villages with a cumulative population of more than 12,000.

Another important energy-related application has been the use of biofuels. In 1999, Udipi Shrinivasa, a former Professor at ME and also the Head of the Sustainable Transformation of Rural Areas Programme (SuTRA), explored the use of Pongamia seed oil as a cheaper and economic alternative to kerosene or diesel, as part of a project funded by the Ministry of Non-Renewable Sources. Based on his findings, the company Dandeli Ferroalloys converted their diesel engines to biofuel-based ones. Under the Karnataka Rural Development and Panchayat Raj Department, biofuel-run water pumps were established in seven villages around Kagganahalli in Kolar district, which had earlier no stored source of water apart from rainwater.

A particular focus has been translating technology in the area of energy

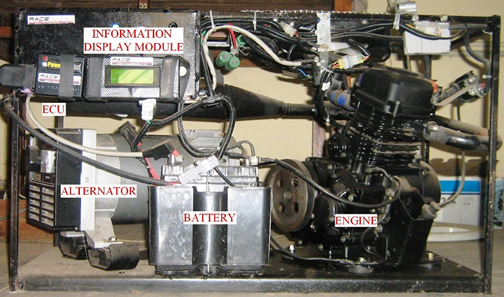

During 2006-2011, as part of two successive projects funded by the Ministry of New and Renewable Energy (MNRE), RV Ravikrishna, Professor at ME, and his team successfully developed a prototype of a small and efficient biogas-fueled 1 kW generator, suitable for powering small households. It was after this project, says Ravikrishna, that “[we] realised that there was a need to do fundamental research into other biofuels such as biodiesels, which was not available at that time.” They were able to perform fundamental characterisation of biodiesels using a unique test facility built in the lab, which could help visualise the fuel spray, droplet formation and atomisation using high speed cameras and laser-based techniques.

The primary focus was on biodiesels derived from vegetable oils, such as those from Jatropha and Pongamia trees. The data generated was helpful for designing engines that could accommodate biofuels with high efficiency. Such research is vital, Ravikrishna believes, because of the impact of biofuels on the environment as well as the enormous role that energy and transportation play in our economy.

At present, Ravikrishna’s lab is working on ethanol and bio-methanol as cleaner and cheaper alternatives to crude oil. Their fundamental research on biofuels and fuel injection technologies for engines goes far beyond the laboratory. The team worked with TVS Motors on small two-wheeler engines and with Ashok Leyland on large heavy-duty engines, and reported that methanol-based engines had higher efficiencies than petrol-based and CNG-based engines, respectively. Their work with Ashok Leyland is “the first indigenous effort to convert heavy-duty engines to methanol-based engines,” he says.

The group is set to initiate vehicle trials for methanol-based engines, as part of a recent academia-industry collaboration funded by the Department of Science and Technology, which was led by his group. The team also recently conducted a study on the life-cycle of automotive fuels from their source to vehicular emissions, on behalf of the Office of the Principal Scientific Adviser to the Government of India. This was a comprehensive study comparing various fuels including hydrogen, and powertrains such as electric and hybrid in addition to the conventional, evaluating both energy use and greenhouse gas emissions. This study is intended to aid the government’s policy decisions in the energy and transportation sector.

Yet another important development in energy research has been the establishment of an experimental supercritical CO2 Brayton cycle test loop facility in 2014, led by ME faculty members Pramod Kumar and Pradip Dutta, as part of an Indo-US clean energy project. This facility aims to develop power plants run on supercritical CO2 (s-CO2) that could replace conventional steam-run thermal power plants. Supercritical describes the state of CO2 at a specific critical temperature and pressure which could yield more energy than steam. Coupled with a solar energy source, s-CO2 run power plants could significantly reduce our carbon footprint.

Green manufacturing

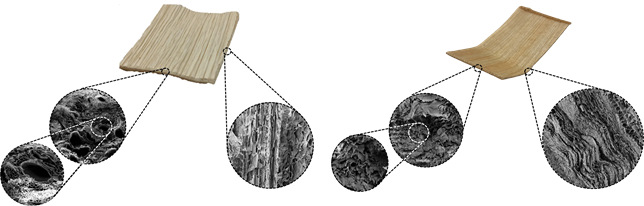

A fitting complement to research on clean energy is research on clean and sustainable manufacturing. The Laboratory of Advanced Manufacturing and Finishing Processes (LAMFiP), led by Koushik Viswanathan, Assistant Professor at ME, works on ‘green manufacturing’ – production practices that are less polluting and that minimise waste. The manufacturing process for single-use plastics has a huge carbon footprint, in addition to the large burden that plastics place on the environment. At LAMFiP, research is being conducted on manufacturing processes for producing sustainable, biodegradable, and eco-friendly plant-based food wares and containers.

In a recent study, the research group studied deformation-microstructure relationships in areca sheath (the protective covering of areca nuts) using micro-computed tomography, scanning electron microscopy and mechanical testing, to understand its formability (the ability to be moulded into shapes such as those required for making cups and plates). Areca, a member of the palm tree family, is native to India and Southeast Asia and is a well-known alternative to plastic, but several issues prevent it from overtaking plastic, Koushik explains. At present, the team is developing solutions to make Areca sheath more stretchable – enabling the manufacture of food or beverage containers in more varied shapes – and less porous in order to delay fluid penetration and seepage, a prerequisite for making food delivery in areca containers possible.

Right: Corresponding sections in the pressed plate reveal significant pore collapse and thinning.

(Images: Harish Dhami and LAMFiP)

Healthcare

Research at ME has also contributed to healthcare in India, through the development of biomedical devices. Work at the Multidisciplinary and Multiscale Design and Device (M2D2) laboratory, led by GK Ananthasuresh – Professor at ME and Dean of Mechanical Sciences – has resulted in products designed to assist in medical procedures or improve one’s quality of life. Among them is a simulator to train medical personnel in endoscopy procedures and an all-mechanical assistive chair to allow the elderly to rise from a chair with minimal effort.

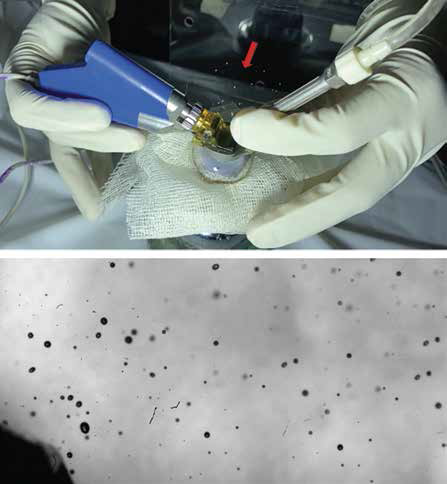

One unconventional application of ME research is in the field of infertility treatment, driven by Santosh Bhargav and Ramnath Babu TJ, former students of the M2D2 lab and co-founders of the startup SpOvum. Intra-Cytoplasmic Sperm Injection (ICSI) is a type of infertility treatment which, as the name suggests, involves injecting the sperm into the egg in the lab or clinic using specialised microneedles. For the injection, the egg is “held” in place by applying a small suction pressure on one side of the egg with the help of a micropipette. As an alternative to the current suction pressure-based method of holding the egg, Santosh and his team have developed a mechanical gripper they call RoboICSI. This product was welcomed positively by the IVF community and has received recognition from the UK Government’s Department of International Trade; the company is currently in the process of getting an international certification for the product, Santosh says.

One unconventional application of ME research is in the field of infertility treatment

Santosh also explains that they are the first company in the world to try and investigate the mechanical properties of the oocytes (immature eggs) during injections, which may be an important predictor for the success rate of the fertility treatment. In addition, the research team at his company has created a comprehensive machine learning model which can predict the success rate of the pregnancy based on several non-clinical and clinical parameters such as age, BMI, sperm quality, and the medical condition of the couple. Santosh credits the research experience and the exposure he received at M2D2 with shaping his thoughts and helping him plunge into entrepreneurship.

While the study of aerosols and fluid mechanics falls squarely in traditional areas of mechanical engineering, Saptarshi Basu, Professor at ME, has translated his expertise in these subjects to modelling the spread of COVID-19 infection. Saptarshi’s work has helped explain how the virus spreads more efficiently in humid and cold conditions compared to a dry and hot environment. “We were the first to show how the droplet vaporisation and aerodynamics contribute to the spread of the pandemic,” he says. On the urgent need for developing a more integrated, holistic model from first principles, he says, “You need to have such a model in place so that you can take decisions quickly. If you can advise the government quickly, then you can save lives and the economy.” In another first, a study published in Science Advances by his group showed that aerosols – which carry a greater risk of disease transmission – can be contained more efficiently when using triple-layered and N95 masks rather than single- or double-layered ones.

(Photo courtesy: Narayana Nethralaya Foundation)

Based on his lab’s work on COVID-19, Dr Abhijit Sinha Roy at the Narayana Nethralaya Foundation approached Saptarshi through a colleague to conduct a COVID-19 risk assessment for doctors and hospital staff performing eye surgeries, such as glaucoma, cataract (phacoemulsification), and LASIK. “This was one area which was not normally looked at in the time of the pandemic,” says Saptarshi. Aerosol generation and their trajectories were studied using cadaver eyes with techniques such as high-speed imaging and shadowgraphy. Based on the outcome of these findings, the hospital staff posted informational videos on YouTube, and a standardised protocol was devised which was shared with ophthalmologists across the nation. Suggestions made for changes in surgery protocol include the use of proper personal protective equipment (PPE), flushing the air at regular intervals, sanitising the room at regular intervals, and inhibiting the use of air conditioners. Currently, nine papers published from Saptarshi’s lab, including the studies on the use of masks, modelling of aerosols, and risk assessment of eye surgeries, have been included in the WHO database for COVID-19 related research.

Science outreach

In addition to core research and industrial ventures, the Department also takes a keen interest in the education sector – an aspect that has deep roots in its past. In 1975, LS Srinath, former Chair of ME, established the Centre for Continuing Education (CCE) which continues to offer several short-term courses and workshops that are open to the public in new and upcoming areas of engineering and scientific methodology, grants for textbook writing, course material development and short-term visitor programmes.

Students of ME are likewise actively engaged in science outreach activities. In 2016, a few of them set up the Science for Rural India (SFRI) group, which organises weekend science classes for high school students based in rural areas of Karnataka, online seminars from distinguished scientists across India, and science magic shows to help kids understand key concepts and engage in the process of science.

Sukriti Kapoor is a PhD student in the Department of Microbiology and Cell Biology at IISc and a science writing intern at the Office of Communications

For more stories on the Department of Mechanical Engineering, please click on the links below:

Making Things Work: 75 Years of Mechanical Engineering

Remembering Arcot Ramachandran

Building a Testament to ME History