Fathima Benazir and Alex D Paul were classmates in school. Many years later, Fathima, a postdoctoral fellow at IISc, began looking for opportunities abroad and happened to share her research work with Alex who comes from the corporate sector. Alex, after going through her work, encouraged Fathima to come up with a product that can have a huge business impact and “not bury her work in big books”. And this is how Fathima and Alex collaborated and co-founded Azooka Life Sciences.

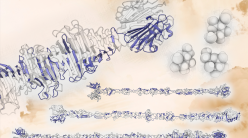

Azooka Life Sciences was formed in July 2015 and is incubated at the Society for Innovation and Development (SID), IISc. In March 2016, they released the first ever food-grade nucleic acid dye called “tinto rang”. Molecular biologists use such dyes to detect DNA and RNA in their experiments.

Credited to be the safest dye, Azooka is now locking horns with giants like Merck and Sigma Aldrich who are the biggest suppliers of Ethidium Bromide (EtBr), the most commonly and widely used nucleic acid dye. But EtBr is a known potent mutagen. Offering molecular biology labs a safer environment by doing away with harmful dyes and its accompanying disposal, Azooka is planning to take over the speciality fluorescent dye/probe industry one step at a time. In a conversation with Connect, Fathima and Alex share their stories of positivity during roadblocks and Azooka’s future.

How was life before Azooka?

Fathima: I’ve always been passionate about science right from school, more so towards biology. I obtained my Master’s and PhD, both in environmental biotechnology, with specialisation in plant biotechnology. I did my postdoc in x-ray crystallography at Prof. MRN Murthy’s lab at MBU as a Dr. DS Kothari postdoctoral fellow. I’m happiest while working in the lab. I did not have plans of making this transition to entrepreneurship earlier as my interest lay only in research and publications.

Alex: I used to earlier work for Zoho, Chennai and my work was mainly focussed on the product management space. Zoho was started in 1996 and they had a mission of bringing out some amazing products out of India. Through my job, I understood product management and I further got into scaling products globally. I have scaled products in different regions and markets such as Latin America, Europe and the Asia-Pacific region.

What is the story behind tinto rang?

Fathima: When we were thinking about building products from my research, we thought about a few things, which could be converted to or developed as products. So we looked at a prebiotic drug for diabetes management. Alternatively, I had some experience with natural dyes during my PhD. We extracted a lot of natural dyes and suggested it to the local community for use in mat weaving. We identified one such natural dye that could bind to DNA and I started working on tinto rang’s development at IISc. (“Tinto” means red in Portuguese and “rang” in Hindi is colour.) It took me about a year to optimise it to a certain extent and another year to craft, formulate and build it to what it is now. Then I had challenges purifying and characterising the molecule. I went on to characterise its DNA-binding ability, staining and fluorescent properties. Luckily, the experiments took direction in a good way. I’m fortunate that every experiment worked.

How would you evaluate the market potential of your product?

Alex: India doesn’t produce nucleic acid stains. We import them at 30% duty. The impression that most people around the world have is that Indians produce cheap products – we have a reputation for copying something and bringing it out cheaper. Our product [tinto rang] is premium and not cheap. We’ve priced it at 3 dollars more than SYBR safe because it and the other market players is arguably safe. At the same time, we are not keeping the product too expensive as we don’t want to defeat the sales of the product. In India, we are doing a replacement offer – we ask them [customers] to pay a similar price to the existing dye for six months and, if they like it, we plan to charge them at normal price. This will give them enough time to realise how much they are saving in terms of the procedures that come with the use of EtBr, such as decontamination and biohazard disposal. This is the advantage we are trying to pass on.

We were targeting biopharmaceutical companies initially. To our surprise, a lot of seed companies were interested. They approached us. Apart from helping customers do away with the hassles of biohazard disposal, they [seed companies] helped us realise that every company spends a lot on compliance, especially when they’re dealing with biohazards. So not dealing with biohazard means they don’t have to buy compliance modules and need not pay for software and modules. So they [seed companies] have signed up for field trials.

Apart from helping customers do away with the hassles of biohazard disposal, they helped us realise that every company spends a lot on compliance especially when they’re dealing with biohazards

Fathima: Most scientists are of the opinion that EtBr is used in very small quantities and may not have a big market. Only after receiving customer feedback did we realise the volumes of usage. With the data we collected, we realised that it is a 50 billion dollar market. In research, we sometimes don’t realise the impact a small chemical can have in terms of business. The consumption [of EtBr] is similar to sugar and salt – though consumed daily in small quantities, its absence cannot be ignored.

Tinto rang packed in a biodegradable box (Photo: Rohini Krishnamurthy)

What about tinto rang’s safety?

Alex: We have a CE certification which is a compliance certification for food grade. CE is a worldwide approved marking, accepted in most of the countries. In the US, they insist more on FDA certification. Our claim to safety is that it is [derived] from a food additive that we are [already] consuming.

Fathima: In addition to that, we have performed certain laboratory toxic studies that prove tinto rang to be non-toxic. The simplest test was observing contamination (growth of microorganisms) in our sample stocks. We saw them and that proves how non-toxic our product is. In our imaging studies, we have tried culturing cells with the dye – it usually doesn’t have implications [the product didn’t have toxic effects on the cultured cells]. We will now be moving to FDA tests. Since we are competing with the giants, we are getting all possible certifications. We are leaving no stone unturned in this matter.

Could you tell us about SID and how it helped shape your business?

Alex: We had support from SID. We knew getting financial support to set up a lab is not very difficult but getting the expertise that IISc has been offering is difficult. They gave us a special innovation grant from which the company was created. We are very thankful to them. Earlier, I used to think SID is pretty slow but the good thing is that there’s absolutely no bureaucracy and hierarchy here. Whatever takes longer time in other incubators, takes shorter time at IISc. We will not be called a start-up after 7 years [of incubation] but I still intend to run a commercial space on campus till they decide to kick us out.

Fathima: SID as such is not a proactive incubator like the others but they help us whenever there is a need and solve our problems immediately!

Alex: That was a year back; now they are swinging into action. SID is like this no-nonsense workplace where nobody is standing in your way.

Fathima: We met a lot of other innovators and they all had tonnes of complaints about policies followed at their incubators including entry and exit policies. When we are fighting some greater challenge, the last thing we want is a gatekeeper. Apart from professional help, IISc has nurtured us. I haven’t seen this in the several incubators we visited. Nothing comes close to what IISc has to offer.

Also, Prof Savithri HS from the Biochemistry department helped us understand problems that start-ups could have and helped us navigate situations. Not just that – she’s been a huge moral support. Just “help” is an understatement. She encouraged us by saying that this is a good way to show to the world that we are also capable of coming up with innovations and not just copying something.

What are the hurdles you had to face as an entrepreneur?

Alex: There is a huge stigma in society presently. My parents couldn’t understand why I quit a well-paid job. Everybody thinks I’m selling podi (“podi” is powder in Tamil). There is some uncertainty in the start-up world. Our parents had reservations in the beginning.

Fathima: My challenges were far more magnified because I am a single mother of two kids and my parents thought I was getting into something I had no idea about. They said it’s better that I play it safe by getting a job, even if I don’t make it big in life. Overcoming the stigma and making them understand was the greatest challenge. It took a toll on us initially – but the manner in which we were progressing and heading forward helped us overcome these personal battles. I think what I’ve realised from this is that keeping myself busy helped me overlook a lot of unwanted things.

Alex: The second [hurdle] was the system itself. Companies in countries like the US, Israel, Singapore and other locations are receiving huge support whereas we have a long way to go. Most grants that fund start-ups today are still funding “projects” and not “products” because I think they themselves don’t realise the market potential of products.

Most grants that fund start-ups today are still funding “projects” and not “products” because I think they themselves don’t realise the market potential of products

Fathima: They are still funding highly technical ego-boosting projects which don’t have any immediate impact or are of no immediate business value. That was a very demotivating factor when we started off fighting this bureaucratic system. So we started to think about which battle was worth fighting: was it the system or the problem we have at hand? We chose to fight the battle that gave us more purpose and meaning.

In your talk at IndiaBioscience on “Careers in Science”, you spoke about collaborations with Sigma Aldrich and the Centre for Nano Science and Engineering (CeNSE), IISc. Can you tell us more about it?

Alex: It is very difficult to compete against giants like Merck and Thermo Fischer Scientific. So we understood that we have to partner with them. We have a better technology and there has been no innovation happening in this area. There has been no alternative to EtBr for years.

We are working with CeNSE to come up with a nanodevice. Thermo Fischer has a complicated system: they also sell EtBr, a UV transilluminator [for viewing nucleic acids] and software [for analysis]. Our dye has its excitation and emission fall in the visible light spectrum while EtBR and most of the other dyes fall in the UV spectrum. So we are trying to come up with a photovoltaic-based system that could facilitate tracking of nucleic acids in the visible light spectrum itself. The idea is to provide a dye, an efficient device and software that can be run on a private cloud.

Fathima– This is something we are expecting in two years from now. The take-home message is that we are not only supplying the chemical to you but also replacing the system (the chemical, hardware and the software). We want our customers to shift from UV-based to safer systems.

We are also looking for collaborations where the dye can find some new applications which are not within our purview. For example, educational kit vendors like Genie and research-based kits like Qiagen: PCR, DNA isolation kits, and plasmid purification kits. We are trying to collaborate with them and make our dye an integral part of their kits.

Apart from the innovation grant from SID, what other funding have you received?

Alex: In a programme run by DST called India Innovation Growth Programme (a collaboration between DST, Lockheed Martin Corporation, and TATA Trust) where they select products that can have a huge impact in India and globally, we were among the top 10 innovators that were selected. So we got to visit MIT and Harvard to understand how schools (tech and business schools) scale innovation globally. They’ve also given us funds for global expansion. We also get mentoring support from Indian Institute of Management, Ahmedabad.

Tinto rang is expected to come out soon in the market. Do you have other products in the pipeline?

Alex: Yes, our next product is called Ano cell stains. Cells stains are rare and not manufactured in India. Such stains currently available in the market have a photostability [resistance to degradation in presence of light] of 40 seconds. To maintain it, an anti-fade agent is required, which is again expensive. Ano cell stains have a photostability of 30 minutes. However, this product hasn’t yet been released commercially because we did not want to steal tinto rang’s thunder. But we’ve had interactions with some of the customers to know its prospects. They showed interest and asked if they could include it in their catalogue before the product is released. We are also looking at bioimaging where fluorophores can help biologists view biological systems. Our focus is also to come up with fluorophores in the Infrared (IR) region. Thermo Fischer and other companies are coming up with IR-based devices which are cheaper in comparison to optical lasers. Currently, most fluorophores in the market don’t fall in the IR range.

How do you see yourself five years from now?

Fathima: We are running field trials [for tinto rang] currently. The reason is that our product could work differently in different environments. So we are collecting feedback from our customers so that we can craft the product well. IISc has mostly new generation devices, which is not the case everywhere. A few start-ups and private colleges use diverse devices – like older versions of transilluminators and some indigenously developed devices. So we are now focussing on collecting information to check for device compatibility and reproducibility.

Alex: We are looking at global expansion six months down the line. We should be in the market by end of 2018 commercially. We are first targeting US and Europe after which we plan to expand to Singapore and South Korea.

Expansion in Europe requires start-ups to pay 30-40% tax. But Netherlands Foreign Investment Agency in Amsterdam has something called as Innovation Box that is letting us set up business by paying them 5% tax for five years. Given the European tax norms which are upwards of 30 %, it is a very useful programme for any start-up. It seems like it’s a good place for innovative start-ups as we don’t have to deal with taxes and other complications.

But Netherlands Foreign Investment Agency in Amsterdam has something called as Innovation Box that is letting us set up business by paying them 5% tax for five years

Fathima, what have you learned from your experience as a researcher and now as an entrepreneur?

From my journey, I have realised that solutions to problems are simple. However great or complicated the technology is, until it is simplified, the solution has no business value as nobody is going to adopt it. We could change our focus and look around for simple solutions to problems because as scientists and researchers we have a tendency to solve complicated problems. I think it is that challenge that boosts the ego of every scientist. This is my valuable realisation through this journey that most of the scientists fail to see. Simplifying solutions can make science more application oriented.