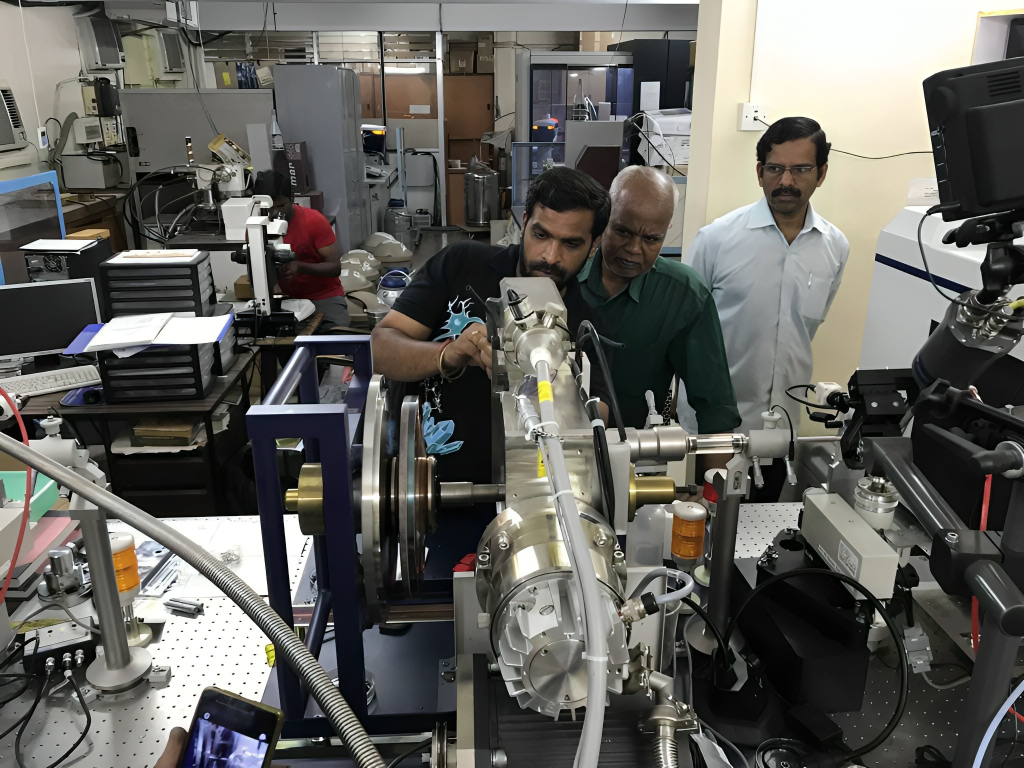

Technicians at MBU’s X-ray facility are crucial to maintaining the high-end equipment

On pushing open the yellow door marked with a bright radiation hazard sign, a wave of cool air belched out by 20 year-old air conditioners greets you. You can hear the low-pitched hum of compressors and generators, also 20 year-old occupants of the X-ray lab at the Molecular Biophysics Unit (MBU), IISc.

Just as Superman’s vision can see through objects, X-ray beams help scientists decode the architecture of nano-sized proteins and other macromolecules. X-rays are used to study protein structure because the wavelength of X-rays is smaller than protein size. The X-ray lab at MBU is a national facility established in the 1980s largely due to the efforts of Mamannamana Vijayan, late professor in the department. The herculean task of maintaining the X-ray machines – worth tens of crores of rupees and requiring continuous cooling and uninterrupted power supply – falls on the shoulders of full-time technicians. Currently, the technicians who work at the lab are Babu PF and Dhruva Kumar.

Dhruva, a former mechanic with an intuitive grasp of machinery, joined the lab in 2011 and is in charge of hardware. Babu, with a background in physics, manages software and assists users with crystal mounting and data collection. Their roles seamlessly blend, with one readily covering for the other. Their personalities also complement each other – Babu’s introversion is balanced by Dhruva’s outgoing nature. Dhruva even brings his seven-year-old son to the lab after school hours, lightening the mood in the lab.

Their knowledge about the facility was passed on by James Paul, a former technician, who has now retired. “James was like an elder brother to us,” says Dhruva. James spent his early career as a grease-stained auto mechanic. His years of taking apart and rebuilding engines made him adept at figuring out how machines work, although his formal education ended at class four. This skill caught Vijayan’s eye, who urged James to join the X-ray lab. Before James, the first technician at the X-ray lab was C Govindaswamy who went abroad to get trained on using the machine. In his autobiography, A life among men, women and molecules, Vijayan writes: “Technical support, initially of C Govindaswamy and later James Paul, was very important [in setting up the X-ray lab]. The other technical personnel who helped were Dhruva and Babu. In fact, we all worked as a team.”

The stuff that proteins are made of

To produce X-rays, electrons are first generated by heating a filament placed in a vacuum chamber. It is essential that there is an adequate supply of chillers to cool down the instrument and that vacuum is always maintained in the machine. To ensure this even during power cuts, the technicians check the power backup regularly and see if there is enough diesel in the generator. They also have to periodically refill liquid nitrogen to guarantee adequate chiller supply.

Once the electrons are generated from the filament, they need to be accelerated using a high voltage. Electrons zipping through the vacuum chamber slam into the anode filament, producing X-rays. The technicians have to replace the filament and align the X-ray beam to hit the protein crystal periodically.

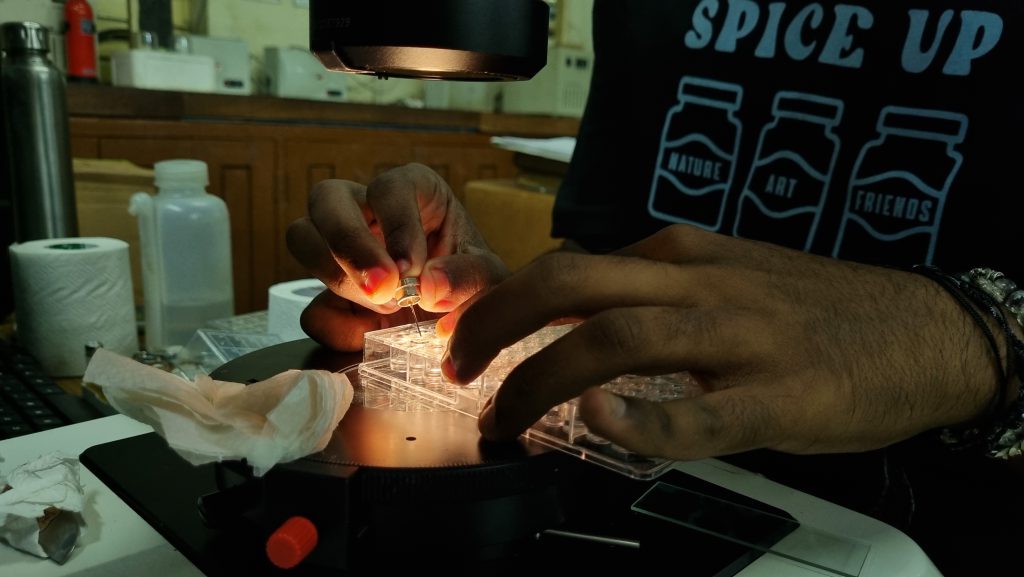

To look at protein crystals, researchers carefully manoeuvre a loop smaller than a millimetre to pick and mount the crystals in the machine. However, the high energy of the X-ray beam may disintegrate the crystal. To avoid this, the crystals are cooled with liquid nitrogen; some crystals may require a cryoprotectant. Then, they are bombarded with the X-rays, which causes the crystals to diffract the rays in different directions. The diffraction pattern is collected on an image plate made of photostimulable phosphor and analysed to determine the 3D structure of proteins.

Keeping these vital components – generators, compressors, and AC units – functional at all times is primarily Dhruva’s role. Babu’s forte is assisting users with mounting the crystal, data collection, and data processing. “Babu sir taught me the working of the X-ray machine and made sure I understood everything, without stopping at just helping me mount the crystal. He is very patient and repeats himself two or three times to help me understand,” says Sankar Mahesh, a PhD student in the lab of Balasubramanian Gopal, Professor at MBU and faculty in charge of the X-ray lab.

“On some days, the X-ray lab runs smoothly, but on some days, all hell breaks loose,” says Gopal. During August 2023, there was a power cut at MBU. The UPS power supply to the X-ray lab was accidentally cut off, and the machines were abruptly turned off. Dhruva had to rush in early in the morning, check the power sources and generators, and restore the power supply. Each machine was then checked, and after days of effort, the vacuum was restored, and the machines restarted.

Keeping vital components functional at all times is primarily Dhruva’s role. Babu’s forte is assisting users with mounting the crystal, data collection, and data processing

Four decades at IISc

Babu has been associated with the X-ray facility for over two decades, and with IISc for 37 years. “My designation has changed many times over the years – from helper to junior research assistant to project assistant to project associate, and most recently consultant,” he says.

With a Bachelor’s degree in physics, he first joined IISc in 1987 as a helper at the Sophisticated Instrument Facility at the Department of Physics (the facility later became the NMR Research Centre). When the faculty member under whom he had worked took a sabbatical, Babu’s project was terminated and he had to look for a new job. He then joined the lab of KP Gopinath, former chair of the Department of Microbiology and Cell Biology as a lab assistant. “A lot of things were new to me in a biology lab, coming from a physics background. I learnt a lot of biology during this period, and it has helped me since,” says Babu. In 1992, he made a request to Vijayan, and joined the X-ray lab.

Over the years, Babu has witnessed generations of X-ray crystallography equipment and researchers. “When I joined the facility, Professor Gopal was a PhD student with Professor MRN Murthy. I am now working with students of students!”

The equipment themselves were difficult to handle in the early years of the X-ray lab, he adds. A critical step in X-ray crystallography is to orient the fine X-ray beam, with a diameter as small as 0.6 mm, to hit the crystal accurately. “I vividly remember my first experience of aligning the X-ray beam with MRN Murthy and his students,” Babu reminisces. Moving the X-ray beam is now mechanised, and aligning it only takes about half a day, compared to about a week earlier. Even computers were a rare sight in those days. “Students used big cassette tapes to store data, and data transfer itself would take days. These days, it only takes a tiny pendrive and a few minutes,” chuckles Babu.

A love for learning

Unlike students, the technicians do not have the chance to take up formal courses in X-ray crystallography. A lot of their expertise is therefore self-taught. Dhruva has decoded the mechanics of the machine by merely looking at its different parts and connections. “My favourite part about this job is the hands-on touch I get with the machines,” he says, smiling.

Sometimes, their understanding of the machine’s working is more in-depth than the instruction manual that comes with the equipment. They need this skill if the machines malfunction because it usually takes a few weeks for representatives from the manufacturing companies – typically based in Japan or Germany – to turn up. The cost of fixing it can also add up to a few lakh rupees. In such cases, the technicians try to fix the machines by themselves. Sometimes, they use spare parts from old machines of the same make to fix the problem. Recently, there was a software issue with one of the machines. The operating system used for the connected equipment is Windows 7, and there were issues with updating it. The vendor said that it would cost lakhs to supply updated software. But Babu was able to fix the issue by identifying a missing library and retrieving it from a previous backup.

‘My favourite part about this job is the hands-on touch I get with the machines’

“Initially, I used to hesitate even to mount crystals of students because I know how difficult it is to obtain protein crystals. Over time, I have become more confident, and I routinely help students with picking and mounting crystals,” says Babu. Now, he is able to crystallise proteins and solve their structures on his own for consultancy projects with industries. He has solved the structure of over 50 variants of insulin by himself. “Anytime you enter the X-ray lab, you can find Babu sir reading a protein structure paper,” says Ankur Singh, a PhD student in Gopal’s lab.

“He suggests when to use a cryoprotectant for the crystal based on his experience. He also helps me with analysing the diffraction pattern to distinguish biomolecule crystals from salt crystals,” adds Sankar. In fact, Babu points out, newly joined X-ray machine company representatives visit IISc to learn from their experience.

Decades of routine work has not diminished Babu and Dhruva’s desire to keep learning. “RNA crystallography is new to our lab, and Babu sir eagerly asks me about it,” says Sankar. Babu also takes help from the students in the lab when he encounters a new protein structure, or in making protein structure infographics. “Students initially learn from the technicians, and then technicians learn from the students,” says Gopal. Sankar adds, “They are very kind. It feels nice to work with kind people around me.”

Crystal clear commitment

The technicians’ commitment extends far beyond their job descriptions. “They treat the X-ray lab as their own. They are ready to come to the lab even during holidays, when students themselves may hesitate,” says Ankur. Dhruva is a common sight even during the weekends, checking the generators and refilling diesel. He is immediately available in case of power cuts or other emergencies at any time of the day and leaves only after the lights come back on.

Once, there was a short circuit and a spark just outside the X-ray lab late in the night. Dhruva came in well after 11 pm and made sure that the X-ray lab was fine. Dhruva also helps the students in setting up the microscope for Open Day demos.

Even during COVID-19, they worked continuously to refill diesel and liquid nitrogen and keep the X-ray lab in order. They also came to the lab frequently and assisted students, who were only allowed in during specific time slots, to complete their experiments.

Although Babu has been working with IISc for 37 years now, he still does not have a permanent position. With hopes of securing a permanent position, he tried to complete a distance PG diploma course in Physics from Annamalai University. But it was very challenging with a full time job that offered no vacation benefits, and he had to abandon his attempt. He still managed to finish a Master’s in Computer Application (MCA), and it has helped him a lot in his job, he says. By the time permanent positions were advertised at IISc, however, he had crossed the prescribed age limit and could not apply for them.

With the X-ray lab becoming a second home for Babu and Dhruva, they are part of every celebration – birthday parties, lab outings, farewell dinners. They have developed a special bond with all the students who have passed through the lab, many of whom continue to stay in touch with them.

“It is very satisfying for us when old students come back and visit us after getting a faculty position,” says Babu, beaming.

Sindhu M is a PhD student in the Department of Bioengineering, IISc and a former science writing intern at the Office of Communications