Researchers at IISc are working on innovative solutions to improve water quality

In August 2011, K Kesava Rao, Professor at the Department of Chemical Engineering, visited the village of Yellampalli, about 100 km north of Bangalore. The residents of the village were faced with a huge problem: water scarcity. To make matters worse, the available groundwater seemed contaminated. The government had set up a reverse osmosis plant to deal with the problem, but the reject water formed a pool nearby, seeping into the ground and cycling back as groundwater. The cattle that drank water from the pool were falling sick, and the elderly who drank the groundwater complained of joint pains.

The team from IISc led by Kesava intended to treat this reject water. “When we first visited the village, we saw that the children at the government school near the Panchayat Office had brown teeth,” says Naga Samrat Maruvada, a former PhD student of Kesava. “We could see signs of dental fluorosis.” Kesava and his group went on to set up a community-level plant to remove excess fluoride present in water.

Fluoride is one of the major contaminants of drinking water. Besides such ions, other contaminants include microbes, heavy metals, and toxic chemicals. According to the World Health Organisation (WHO), contaminated drinking water causes more than 5 lakh deaths each year.

An expert in granular flow, Kesava made his foray into water treatment with a desire to make some social impact through his work. “I used to read newspaper reports about problems with water contamination, particularly excess fluoride in water, and wanted to do some applied research that would benefit people,” he says. Thus, Kesava collaborated with a friend, Arup K SenGupta, Professor of Civil and Environmental Engineering, Lehigh University, USA, to set up the community-level defluoridation plant at Yellampalli in order to treat the reject water from the existing reverse osmosis unit. Arup had earlier developed an adsorbent to remove arsenic from contaminated water, and the duo wanted to use the same technique at Yellampalli. “It was a polymer resin with zirconia nanoparticles in it,” Kesava says.

As Kesava and his colleagues later found out, treating this water was more complicated as it was rich in other ions like nitrite and nitrate ions. Moreover, the anti-scaling agents used in the reverse osmosis plant corroded the columns of their defluoridation plant, causing the water to leak. Kesava and Arup then decided to abandon the project.

Kesava’s group would eventually go on to pursue the idea of removing excess nitrogen from water when Maruvada received an Erasmus Mundus fellowship. As part of this project, they developed a microbial fuel cell containing a microbe found in seawater to remove nitrogen.

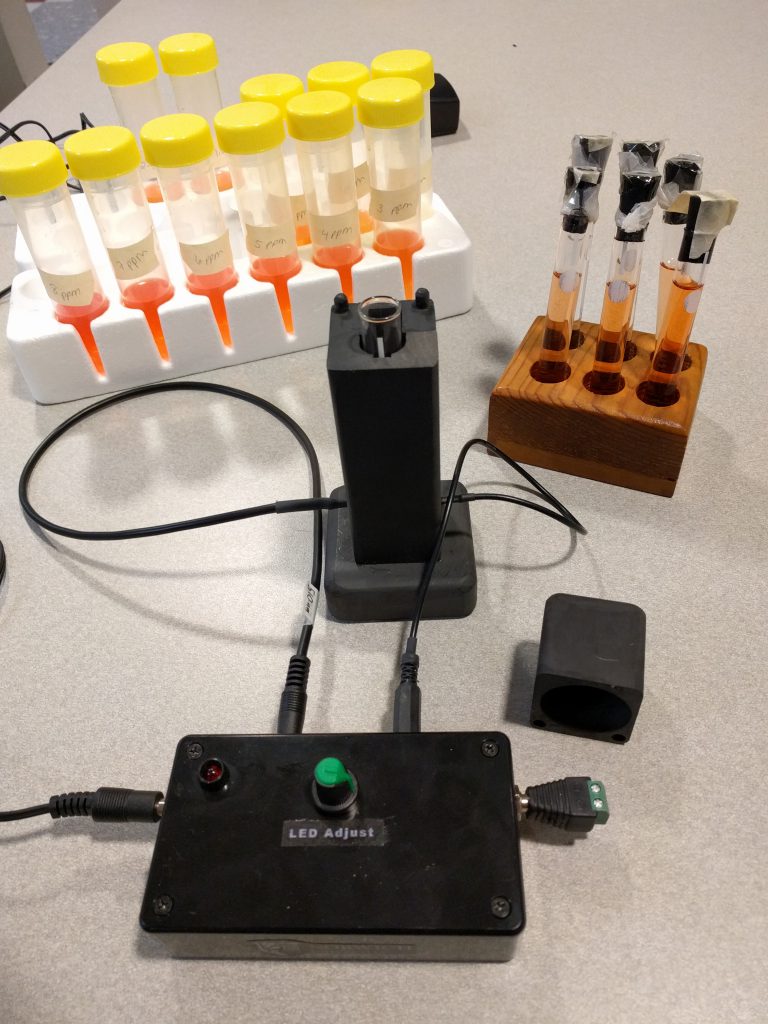

Kesava and his friends, Seth H Frisbie and Michael W Prairie, at Norwich University, USA, recently developed a low-cost spectrophotometer

Kesava and his friends, Seth H Frisbie and Michael W Prairie, at Norwich University, USA, recently developed a low-cost spectrophotometer – a device that detects components in water by measuring the amount of light of a specific wavelength passing through it – that could detect fluoride, manganese, and iron in water. The device, which cost USD 63, was tested successfully both in the US and India. The idea was an outcome of discussions during a water conference that was held at IISc. In fact, Kesava’s journey in water research came full circle with this project, as his first project in the field – before the Yellampalli project – was to develop an LED-based spectrophotometer to estimate fluoride levels in water. This was a collaboration with his friend Govind Rao, a Professor of Chemical, Biochemical, and Environmental Engineering at the University of Maryland, Baltimore County, USA. Kesava and Govind, who do not like the idea of patenting products that benefit society, have detailed the working of the instrument they developed in a paper they published in the now defunct journal Field Analytical Chemistry and Technology in 2008. Similarly, Prairie and colleagues also published the details of the instrument he recently developed in PLOS One in 2020.

Another recent effort to remove contaminating ions from water has come from the lab of Partha Mukherjee, Professor at the Department of Inorganic and Physical Chemistry. His group has designed a molecular nanocage that selectively removes fluoride from groundwater. “Each cage can bind to six fluoride ions,” Partha explains. The group is continuing to work on developing cages that can bind to other anions like chloride. “Chloride is a major issue in the treatment of industrial wastewater, especially in steel industries, where the wastewater can corrode steel,” he says. Although the method has only been tested at laboratory scale now, they are interested in engaging with people who may want to scale this technology up.

One limitation of the method, as Partha explains, is that these cages dissolve in water. “One way around it is to use these cages in columns so that the cages can be recovered easily after treating water,” he adds. Earlier, Partha’s lab had also developed a compound that kills bacteria in water.

Such technologies are the need of the hour as more than 700 million people live in countries with high and critical levels of water stress. Moreover, at least 3 billion people are unaware of the quality of water they use owing to a lack of monitoring. These growing concerns about water scarcity and contamination have led the United Nations to lay out a Sustainable Development Goal (SDG) to “ensure availability and sustainable management of water and sanitation for all.” At the national level, the National Green Tribunal (NGT) established more stringent norms for water quality, proposed by the Central Pollution Control Board (CPCB) in 2015. According to the norm, Chemical Oxygen Demand – a measure of organic matter present in water represented as the amount of oxygen needed to oxidise them – was restricted to 20 mg/litre; Biological Oxygen Demand – the amount of oxygen consumed by microbes while they decompose organic matter at a specific temperature – at 10 mg/litre; and the total nitrogen level at 20 mg/litre.

Such technologies are the need of the hour as more than 700 million people live in countries with high and critical levels of water stress. Moreover, at least 3 billion people are unaware of the quality of water they use owing to a lack of monitoring. These growing concerns about water scarcity and contamination have led the United Nations to lay out a Sustainable Development Goal (SDG) to “ensure availability and sustainable management of water and sanitation for all.” At the national level, the National Green Tribunal (NGT) established more stringent norms for water quality, proposed by the Central Pollution Control Board (CPCB) in 2015. According to the norm, Chemical Oxygen Demand – a measure of organic matter present in water represented as the amount of oxygen needed to oxidise them – was restricted to 20 mg/litre; Biological Oxygen Demand – the amount of oxygen consumed by microbes while they decompose organic matter at a specific temperature – at 10 mg/litre; and the total nitrogen level at 20 mg/litre.

These revised, more stringent, guidelines that the NGT then enforced also provided the motivation and thrust for the work of Sanjiv Sambandan, Assistant Professor at the Department of Instrumentation and Applied Physics. When Sanjiv started his independent research group in IISc in 2010, he noticed that there were several technologies to treat water that went into homes for usage – technologies that take, say, contaminated tap water and improve its quality. “But there was nothing much being done about water going out of a house or industry,” Sanjiv says. Having identified this gap, he started exploring ways to “reclaim water and reuse it – if not for drinking, at least for things like landscaping, washing cars, and so

on.”

Traditionally, such wastewater that was let out of a house or industry was finally treated at a centralised Sewage Treatment Plant (STP). These plants are typically run using techniques that involve the use of microbes along with chemicals and membranes to treat water. Such treatment technologies that use chemicals or membranes pose a logistical barrier as one has to procure and store them, Sanjiv explains. Besides, its use and maintenance also requires expertise.

Under the revised guidelines, first, the Pollution Control Board ordered that all water treatment be decentralised. Incidentally, Sanjiv’s group was working with this thought in mind, envisioning a technology for decentralised water treatment, while avoiding the pain points of using membranes and chemicals, and the requirement of expert maintenance for the treatment process. They used the concept of electrocoagulation — a technology where two plates are placed in water and DC voltages applied to facilitate an electrochemical reaction. “The positively charged metal ions would neutralise all anionic pollutants and Van der Waals forces coagulate these pollutants. This is like an electronic alum,” Sanjiv explains. His group modified the system to include the use of controlled pulsed current along with using the geometry of curved plates to enhance coagulation.

Second, NGT made water treatment norms more stringent, which many STPs were struggling to meet due to fluctuating water load and poor maintenance. In addition to much higher water quality that the technology provides, it costs less than what an STP would cost. “The technology is modular, does not require any civil construction, and can be easily deployed at different sites,” says Prabha Nagarajan, Director of Openwater.in, the start-up that Sanjiv founded with this technology.

The technology has gained quite some traction and won several awards. They have started deploying units in a few sites in Bangalore and are running a social impact project as well. Through the start-up, Sanjiv and his colleagues are looking at developing new products and taking their current product to the market.

“What came out from my lab is the technology, a basic idea. But there are a lot of steps involved in launching a product, and that comes with industry experience. We have our directors, Prabha Nagarajan and Nitin Parekh, who do that very well,” Sanjiv says.

A talented and enthusiastic team of scientists, engineers, designers, fabricators, and an administrator works shoulder-to-shoulder with the top management out of a container located close to the STP at IISc, innovating new products and designs to meet the market’s needs. “I am grateful to our excellent team of engineers who have made all this possible,” Sanjiv says.

Although their product is close to drinkable quality, Sanjiv and team do not make the claim. “Our technology cannot bring down the levels of dissolved solids in water to below 50% of input levels,” Sanjiv says, explaining the limitation of the technology.

“If potable water is required, we could consider this as a pre-treatment step,” Sanjiv says. “This could do all the heavy lifting before it is connected to a reverse osmosis line to make it drinkable,” Prabha adds.

In keeping with their vision of providing clean water for all, Openwater is working on a social impact project at Mavallipura, a village about 20 km north of Bangalore city. The quality of groundwater here is extremely poor due to poor solid waste management of the landfill next to the village. The waste leaching from the landfill has contaminated the water sources that the residents use. Sanjiv and team hope to provide clean, reusable water for the residents of Mavallipura using their water treatment technology.

Joel P Joseph is a PhD student at the Centre for BioSystems Science and Engineering (BSSE), and a former science writing intern at the Office of Communications, IISc