From 1945 to 1948, a programme at the Department of Biochemistry provided soya milk as a nutritional supplement

The Second World War ended with acute scarcity of food and milk in many parts of India. A year before the war ended, in September 1944, IISc created a new post for a Lecturer in Food Technology. It was filled by a scientist named Sasank S De, who had just transferred from the University College of Science at Calcutta (now Kolkata) where he had worked on different enzymes obtained from snake venom, from 1939 to 1944. He first became involved with soya in 1943 during the Bengal Famine, when he worked with BC Guha of Calcutta University to make soya milk for starving infants. Together with my grandfather, V Subrahmanyan, who was the head of the Department of Biochemistry at IISc, De worked on a unique programme that not only studied whether soya milk could supplement nutrition in children, but also involved feeding soya milk on a regular basis to thousands of children in Karnataka for around four years.

Towards the end of the war, India was not producing as much milk as it needed and malnutrition was a dire problem. It was thought that substitute milks could be made by blending proteins derived from different sources, particularly from oilseed residues including soya bean and groundnut. IISc’s Annual Report of 1944-45 includes the following paragraph in a description of the work on soya milk: “Although several attempts have been made, in recent years, to popularise the use of soya-bean in India, much headway has not been made because of inadequate knowledge in regard to the uses of the bean. Soya-bean does not make a good dhal and if merely boiled and used, it has a low digestibility and its protein has a poor biological value. The high nutritive value of the bean, however, stands revealed when the bean is processed to yield a milk. This is a form in which soya-bean is mostly used in China, Japan, America and other countries.”

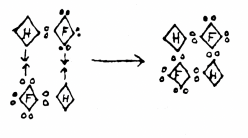

In De and Subrahmanyan’s recipe, initial soaking was carried out for two days in any suitable container to germinate the beans. If these beans were then dried, the skin was more easily removed. A modified coffee pulper (which was not efficient and required a lot of water) was used to remove the hulls. Kernels that had been dried were soaked again. The soaked kernels were placed in a steam-jacketed pan along with some water and the temperature was brought to 70 degree Celsius and maintained for 10 minutes. The kernels were then washed with water till the beans were almost white. A mechanical grinder, stone edge runner or granite triple roller mill was used to grind the beans to a paste. (An uncle of mine, S Sundaram, was one of three of Subrahmanyan’s children that lived on the IISc campus. He remembers that the company Larsen & Toubro supplied some of the machinery involved, and that the whole process was carried out behind the old Biochemistry building at IISc.) The fine paste was then boiled with three times as much water containing sodium bicarbonate or glycerine to extract the bitter taste and give it a more appealing colour. Boiling was continued for 15-20 minutes after frothing reduced. The soya milk was filtered through woven cloth while hot. This prevented part of the cream from being lost. Salt and sugar were added, and the milk placed in a cold room prior to distribution. Calcium salts were added to the finished product. Milk could be further extracted from the residual paste using a wooden or metal press.

In rat feeding trials, soya milk supported growth almost at the same level of cow’s milk

This soya milk was used in animal studies, and it was shown that in rat feeding trials, the soya milk supported growth almost at the same level as cow’s milk. In later studies, De and Subrahmanyan found that the biological value (the amount of a protein absorbed by the body) of soya bean dal was only 55, while that of the milk was 80. However, soya milk had a digestibility of 92% while cow’s milk had 88%. Soya milk carried with it enough B complex vitamins, and could ably supplement a rice diet.

In another paper written with a student named HSR Desikachar (who years later was my own guide), De investigated why the soya bean had poor nutritional properties. They discussed the role of inhibitors in soya beans as the reason for this. They found that the removal of trypsin inhibitors by acid extraction or any heat treatment, particularly wet heating or wet autoclaving, increased the nutritive value of soya. However, there was no change in trypsin inhibitor activity during germination, a process that vastly improved the nutritive and biological value of soyabean. In 1948, De, Subrahmanyan and Desikachar noted that only autoclaving soya milk at a pressure of 20 lbs or 25 lbs destroyed most of the trypsin inhibitor activity in lab studies.

Alongside their studies in the lab, they began human feeding trials as well. In an initial study, 129 children aged between a few months and six years were either fed cow’s milk as a supplement or soya milk. Four-month-old infants did better on soya milk, while older children responded to both milks. Hospital feeding trials were initiated in collaboration with Dr Mary C Albuquerque at the Vani Vilas Hospital. The Indian Research Fund (later renamed the Indian Council of Medical Research), the Department of Food (later renamed the Ministry of Food and Agriculture) and the then Military and Civil Station of Bangalore funded a project in which IISc prepared soya milk and carried out animal experiments prior to a mid-day meal scheme for children. However, for the school feeding programme, the soya milk was not prepared using De’s and Subrahmanyan’s method of germinating soya, but with flour using a process developed by KP Basu based in Dhaka (now in Bangladesh), as it yielded more milk.

In a biographical note on Subrahmanyan for the Indian National Science Academy, CR Krishna Murti, a former student of his, writes: “For a long time, Professor Subrahmanyan was obsessed with the problem of the nutty flavour of the milk. It was found later that this could be overcome partially by fermenting the milk to curd.” This tastier form of soya milk was mixed with rice and fed to the children in the programme. In 1945-46, IISc produced 550 lbs of soya milk a day. The majority of it was converted to curd and mixed with rice for feeding 1,600 primary schoolchildren.

Around this time, IISc developed a pilot plant for the manufacture of soya milk. At its peak in 1947-48, the Bangalore School Feeding programme saw 6,000 schoolchildren given curd prepared with over 600 lbs (around 272 kg) of soya milk. Of the children in the school feeding programme, three hundred were divided into three groups of 100 each. Group A was fed with cooked rice and separated milk curd, Group B with rice and soyabean curd, and the control Group C received no extra supplemental feeding. The weight and height gains were similar among children in groups A and B, while the values were lowest for the children in Group C. In addition to the school feeding programme, which ended in 1948, multiple experiments with soya milk were conducted between 1945 and 1948 with children in local orphanages and convents, according to the IISc Annual Reports.

They suggested that soya was on the one hand a food supplement, and on the other, a milk extender

De and team didn’t just consider soya milk as being beneficial for children. They also suggested that soya milk could be used in tea and coffee, or to make curds and buttermilk. They suggested that soya was, on the one hand, a food supplement, and on the other, a milk extender. In 1950, IISc was even asked to conduct feeding trials in the army. Two hundred recruits were fed soya milk, and another two hundred were fed blended milk to evaluate the benefits of including soya milk in army rations. Preliminary results showed improvement in both groups.

Around the same time, IISc also conducted plant breeding research on soya under botanist and horticulturist BS Nirody. It imported ‘Bansei’, an American variety of the soya bean, from California “as a foundation seed for acclimatisation and selection for a more productive strain,” according the Annual Report of 1949-50, which continued, “Results so far obtained are most encouraging and part of the acclimatised seed of the third generation was supplied on request to the Army Department at Dehra Dun and New Delhi under its Food Production Scheme. A fairly large successional crop is now in progress for further improvement in this direction.” By 1952, the Annual Reports mentioned a new soya bean named Tata5, which was evolved at the Institute and supplied to researchers in China, the UK and Nyasaland (now known as Malawi).

However, the soya experiments and feeding programmes were not without logistical problems. The soya bean is native to East Asia, and at the time that De and Subrahmanyan were studying it, it wasn’t widely available in Karnataka. Obtaining soya beans for a large-scale feeding programme from north India was difficult, and this was resolved through the intervention of Sir Philip Gaisford, the Resident in Mysore. The whole feeding programme was approved by WH Kirby, Rationing Adviser to the Government of India, and carried out with the aid of PM Jayarajan, an ICS officer who was the chief magistrate and collector of the Civil and Military station. Nevertheless, its limited availability was seen as a hurdle.

Another, and more significant hurdle, was the dismissal of research on the value of soya. In 1946, the Soya Bean Sub-Committee of the Nutrition Advisory Board concluded their ‘Report on Soya Bean’ saying they were “not in a position […] to advocate immediately the encouragement of the production of soya-bean on a wide scale in India as a substitute for Indian pulses. The question should, however, be reconsidered if and when further evidence on the nutritive value of soya bean becomes available.” In Science and Culture in 1946, De and Subrahmanyan wrote (perhaps partly in response): “Our attempts are based on the results of a very extensive series of scientific studies published in Current Science, Science and Culture, annals of Applied Biochemistry and Medicine and other journals. […] Our findings are open to verification by any investigator who may be interested. To further demonstrate and apply our findings, we require the co-operation of the agriculturist to grow the bean; of the Government and the administrators for funds; of engineers in fabricating improved types of equipment, education and public health authorities for facilities and co-operation in conducting further trials, of medical colleagues for systematic observations, of the consuming public for sympathetic interest and helpful suggestions, and of fellow scientists for sympathy.”

While soya bean investigations formed a major portion of the work done by De and team, they also did work on other nutritive foods. One area they worked on was rice gruel. They noticed that rice was often cooked with excess water on an open flame, and when the rice was drained, this nutrient rich water was wasted and thrown away. They appear to have sourced large quantities of this rice gruel (kanji) from the military, boiled it with roasted wheat flour and added sugar and soya paste (which was left over after the milk was pressed out of soya) to it. This mixture was cooled and set as a pudding with cardamom powder or vanilla essence for flavouring. The military would then deliver the kanji pudding to schools. The researchers suggested that big towns could produce kanji pudding using kanji from large feeding centres, and feed this to the poor and young schoolchildren as a public feeding programme. The researchers also observed that in homes, kanji could be mixed with cow or buffalo milk and set to a curd. “This would definitely be an advantage to homes which prepare their own curd and buttermilk and which could do with some extra supply,” they wrote in March 1947.

Another vegetable-based milk the researchers considered at the time was groundnut milk. Good quality, mature groundnut kernels were mildly roasted to remove the testa or skin of the seed. The kernels were then ground to a fine paste in a roller mill or other suitable grinding machine. This paste was mixed with a quantity of water and filtered, and its pH adjusted to about 7.0. The milk was then deodorised with steam, cooled, fortified with minerals and vitamins, and homogenised. To the prepared milk, invert sugar was added, and the milk was seeded with buttermilk prepared from cow’s milk curd. After 12 hours at room temperature (26-28 degree Celsius), the curd set to a thick mass. A feeding experiment, extending over a period of 6 months, was carried out on 42 girls aged between four and 11 years in a boarding home in Mysore to assess the value of adding a supplement of groundnut curd to the diet. Results of a statistical analysis showed significant improvement in the weight, height and nutritional status of children receiving the supplement of this curd over those in the control group (which received a pudding made of corn starch and cane sugar instead, to equalise the caloric intake in both groups). The authors expressed their thanks to the authorities of the Good Shepherd Convent in Mysore for providing facilities for conducting the experiment.

In 1950, Subrahmanyan left IISc to be the first Director of the Central Food Technological Research Institute in Mysore. His interest in vegetable milks was extended to the use of groundnut there. Milk from groundnut and soya bean fortified with minerals and the amino acid methionine as a substitute to milk was made there. Experiments were conducted on the nutritional status and general health of school children on diets supplemented with those vegetable milk and curds. Daily supplementation of 12 ounces of vegetable milk showed significant improvement in the growth and nutritional status of south Indian children, as revealed by the increase in their weights and heights, and higher retention of nitrogen, calcium and phosphorus. Research on soya and other vegetable milks continued in IISc under the Food Technology Section. However, De moved on in 1951, and eventually after he retired, he served as Senior Food and Agricultural Industries Officer for the Food and Agricultural Organisation (FAO) at the UN, based in Thailand.

In August 1955, research on milk substitutes supported by the ICMR was presented at a meeting of the Nutrition Advisory Committee held in Mysore. According to the report from the meeting, titled “Milk Substitutes of Vegetable Origin”, vitamins, minerals and fats could be obtained from sources other than milk. The importance of lactose as a nutrient was questionable and any sugar could be used as a substitute. The report then compared the composition of whole and skim milk powder with that of almonds, cashew, coconut, groundnut and soya bean, and gave a detailed account of research on soya and groundnut milk. The report identified two key obstacles to the widespread use of milk substitutes: unfamiliarity and prejudice, and the fear that such products would lead to adulteration of animal milk. It ended by saying, “A favourable feature about the production of milk substitutes, especially in India, is the abundance of raw materials and the cheapness of the processed product which would bring it within reach of a large section of people who can ill-afford to buy them at the prevailing high prices.”

On a personal level, I find the soya milk investigations fascinating because they were so much more than just scientific experiments. They included trials on children in orphanages and welfare centres, which were overseen by the health authorities – but those norms were different from the ethics standards for trials using children today. Even so, the researchers were responding to an enormous challenge facing India, and were personally driven by their experiences of famine or of witnessing famine. I recall my guide, Desikachar, telling me that as a child experiencing famine in Chamarajanagar district of Karnataka, his mother would feed him sorghum, which was all that was available, but because she did not know how to cook it properly, he struggled to eat and swallow it. De had certainly seen the horrors of the Bengal famine in Kolkata, and Murti writes that in a 1945 lecture, Subrahmanyan spoke about seeing malnourished children and how “that vision had become permanently etched on his mind in his younger days and which in turn led him to take a vow to do something to relieve those distressing conditions.” I find it remarkable that at IISc, they even built a plant to manufacture large quantities of soya milk to feed thousands of children who were not part of the scientific experiments. It was a humanitarian project as well as a scientific one, and supplementing food for children remains a priority for most state governments – that’s what makes the soya milk project such a special one.

Arun Chandrashekar has an MSc in Biochemistry from MSU Baroda and he obtained a PhD in Food Science from University of Mysore under the guidance of Dr HSR Desikachar. He worked at CFTRI in the areas of biochemistry, molecular biology and microbiology.

With input from Deepika S