It can help make the best use of available resources, says IISc’s Deputy Director

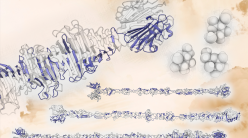

Microorganisms, often described as protein-producing factories, are widely used by industrial biotechnologists to produce human proteins of therapeutic interest. One such example is human insulin, produced by the bacterium Escherichia coli (better known as E. coli) and more recently, by the yeast Saccharomyces cerevisiae.

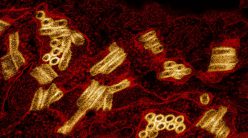

To produce such protein molecules, industrial biotechnologists cultivate microorganisms by housing them in vessels called bioreactors, and providing them with other resources like nutrients and oxygen. But the challenges of obtaining maximum protein yield mean that this process – fermentation – is not as simple as it sounds.

These challenges were discussed by Jayant M Modak (Deputy Director, IISc, and Professor of Chemical Engineering), in his Institute Colloquium on 17 April 2017. He explained how he uses modelling techniques to help better understand both the working of a biological cell and the functioning of a bioreactor.

He explained how he uses modelling to understand both the working of a biological cell and the functioning of a bioreactor

Expanding on this, Modak spoke about the progress his lab has made in collaboration with Rajan R Dighe (Professor, Molecular Reproduction Development and Genetics, IISc) in optimising the fermentation process.

“We used a well-characterised yeast called Pichia pastoris because it requires less fermentation time, produces complex proteins, and the time of production of proteins of interest can be controlled,” he said. The focus was to produce a glycoprotein (protein attached to sugar) called Human Chorionic Gonadotropin (hCG), used in fertility treatment.

But they encountered a few pressing problems with Pichia as a protein expression system. The first was difficulty in obtaining maximum protein yield because the yeast consumes two different carbon sources. Protein production is activated only in the presence of methanol, but glycerol, which boosts cell growth, does so at the cost of protein yield. As both carbon sources have different roles, fermentation is carried out by adding them at a pre-determined rate instead of adding them together, and the time at which the switching is done between the carbon sources needs to be determined. The second was that hCG produced from Pichia was not as biologically active as the human form. This can be attributed to the difference between the sugar attachment patterns in humans and in yeast. The third was decreased cell growth as Pichia is manipulated to produce human proteins.

To strike the optimal balance between the two carbon sources, Modak and team used genetic algorithms to select the fittest microbial population by varying the nutrient feeding patterns against different time periods. To make hCG biologically active, they employed genetic engineering tools. In an attempt to reduce the burden on cell growth, Modak’s team studied metabolism in Pichia in response to glycerol. Talking about the future goals, Modak said, “Our focus will be to study the effects of eliminating proteins that could possibly affect cell growth.”

Besides his work on modelling, Modak’s lab has developed technology to treat environmental pollutants and biologically remove toxic metal ions from solution.

Besides his work on modelling, Modak’s lab has developed technology to treat environmental pollutants and biologically remove toxic metal ions from solution.

He quoted an example of how he helped a coffee processing plant in Chikmagalur, Karnataka treat its effluents that had high Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) levels. “These pollutants, when released, affect aquatic ecosystems by depleting the oxygen levels,” he said. To mitigate this, Modak and team designed a bioreactor using partially decomposed leaves. After installing the bioreactor, the pollutants were reduced by a factor of five from the initial amount, which according to him, is due to the action of microflora present on these leaves.

Modak and his team also work on understanding fluid flow in the bioreactors by performing simulations. They are currently trying to study this in an 8,00,000-litre algal pond being set up at the Council of Scientific and Industrial Research’s (CSIR) Central Food Technological Research Institute, Mysore.