The ongoing debate on digital vs. physical prototyping

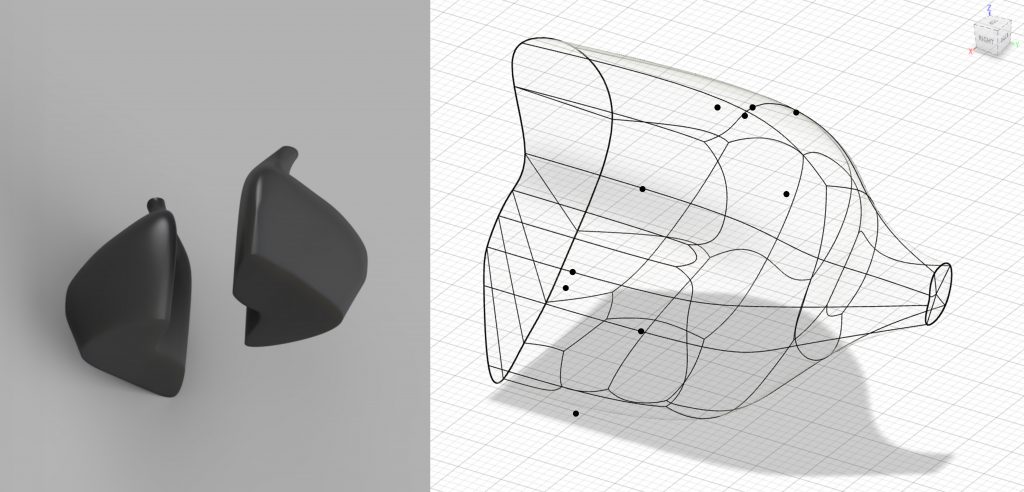

It was supposed to be a simple task. As part of our coursework project on Applied Ergonomics at IISc’s Department of Design and Manufacturing (DM; formerly known as the Centre for Product Design and Manufacturing, CPDM), my team wanted to design earphones with the perfect ergonomic fit, which align most closely with the human ear. We spent hours refining our prototype. We extracted ear dimensions from 3D ear models, designed earphones, ran simulations, and built a CAD model. After multiple all-nighters, we were finally set to print at around seven in the morning, weary but hopeful.

Six hours later, caffeinated and exhausted, the print was finally complete. One of my teammates took out the printed earphones and tried them on. To our embarrassment, they did not fit. Our mistake was glaringly obvious: We had directed the ear tips away from the ears rather than toward them, making the design unusable. With only an hour to go before the presentation, the project was a failure. The mistake was small, almost imperceptible in the grand design process, but its consequences were conspicuous.

If we had started with quick, handmade foam models, could we have caught this error before the design was locked in? The mistake cost us time, material, and momentum. But we learned a valuable lesson – in design, especially when working under pressure, decisions on how, when, and why to prototype make all the difference.

The design process

Generally, the engineering design process is a step-by-step method to build useful things that solve problems. It starts with identifying a problem, then researching and brainstorming ideas. After that, design engineers plan and build prototypes – a rough version of the final solution. We test it, see what works and what does not, and then improve the design. Above all, it’s the iteration of ideas that matters. It’s like putting together a puzzle – but here’s the catch: you’re the one who has to design the pieces.

It’s like putting together a puzzle – but here’s the catch: you’re the one who has to design the pieces

The process significantly depends on how those pieces are made: physically, digitally, or using a combination of both. Before digital tools arrived, prototypes were built by hand. Designers carved wood, bent wire, and glued bits of foam together, chasing the shape of an idea with whatever their workshop could spare. It was slow, sometimes messy, but mistakes were visible and tactile. When computers entered the picture, screens replaced drafting tables, and digital models let designers test, tweak, and discard ideas without touching a single tool.

For a while now, the question of when to make digital and when to make physical prototypes has been something of an obsession for me. Maybe it is because I keep returning to the same debate across mediums – digital art versus traditional, e-books versus paperbacks – and how digitisation is infiltrating everything. To see how others felt, I conducted a poll among the Master of Design (MDes) students at IISc: “At gunpoint, if you had to choose between digital or physical prototyping, which would you choose?” To my surprise, most chose physical. Given the scale of our projects as students, it is usually much easier to design a 3D model on the computer and print it than to source hardware and modify it to build a prototype. Physical prototyping demands much more time and resources, especially when balancing coursework and tight deadlines. Yet, despite the challenges, most still favoured the hands-on approach.

“There’s something about holding the design in your hands that no screen can replace,” says Yash Dudhpachare, a second-year MDes student of DM. “I like that physical prototypes give immediate feedback when you touch and observe them in real life.”

Physical in a digital world

In the real world, too, there seems to be a propensity for physical prototyping. Sankar Balasubramanian, PhD scholar in the Department of Mechanical Engineering at IISc who currently works on Computational Product Design, offers a perspective from the automotive industry. “In automotive design, form comes first,” he says. The process begins with sculpting full-scale clay models to capture the essence of the design. These models then undergo testing under various conditions, revealing how light and shadow interact with the surface. This helps assess the aesthetic appeal of the vehicle by refining the curves and edges. Later, this model facilitates collaboration between designers, engineers, and marketers to not only visualise the product but also plan for its performance.

Once the form is established, the process moves into digital refinement. Through weeks of design and validation through simulations, the team creates a fully functional physical prototype, complete with moving parts. Often, even after extensive digital simulations, the physical version can still reveal unexpected flaws. “Solving one problem can create another,” says Jegannathan Kannan, from the Body Design team at a leading car manufacturing company. In one of their product designs, they noticed a discrepancy in the assembly of the clamp-rod system; although it performed perfectly in digital simulations, it failed during physical testing. “It looked perfect on screen, but the physical fit was off by just enough to stop the whole assembly. We modified this, but later learned that this had led to another problem.”

While digital simulations are more cost-effective and time-efficient, they might miss critical aspects in the design

This limitation of digital prototypes is precisely why physical models seem to remain indispensable. While digital simulations are more cost-effective and time-efficient – especially in fields like automotive, aerospace, and biomedical engineering, where materials are expensive and regulations are strict – they might miss critical aspects in the design.

This becomes even more crucial for products at the nanoscale. “When operations scale down, digital models often struggle to capture the fine details of physics,” says Saravanan Murugaiyan, PhD scholar in Product Design and Engineering, DM at IISc. His research focuses on developing a medical device intended for implantation in the brain, where precision is crucial. While the device is the size of a human hair, its electrodes that connect to the neurons measure only a few micrometres. It requires rigorous testing, starting with small animals like rodents, then progressing to pigs, and eventually non-human primates before being considered for human trials. In such cases, the margin for error is almost nonexistent. “When safety is critical, digital simulations alone are not enough,” says Saravanan.

The human touch

Komal Shah’s journey from student to entrepreneur began at DM, where she honed the skills that would later shape her startup, Periwinkle Labs, currently incubated at Foundation for Science, Innovation and Development (FSID) at IISc. Komal’s startup is developing wearable garments, like a pair of shorts, designed to provide adaptive stimulation for the treatment of urinary incontinence. This would enable patients to manage their care at home and reduce the need for frequent clinical visits.

Komal recalls how the resources and mentorship at DM allowed her to bridge the gap between theory and practice. “What I really learned at DM was to reason and rationalise every decision as a designer,” she says. “It wasn’t just about making something that looked good; it was about fulfilling a real user need with care, backed by data and understanding.”

‘For fabric-related issues involving fit, flexibility, and comfort, there’s no substitute for a physical prototype’

Komal quickly realised that in the field of pelvic health, her prototyping approach needed to balance both form and function. “For fabric-related issues involving fit, flexibility, and comfort, there’s no substitute for a physical prototype. We drape it on mannequins or real users and see how it fits. But when it comes to electronics, like battery placement or signal flow, we start with digital models. It’s faster, and we can spot obvious flaws before we commit to hardware.”

Using hybrid prototyping approaches is particularly necessary in healthcare-related products. Alumnus Deval Karia, CEO and co-founder of OpenMedLabs – also incubated at FSID – exemplifies this by following a User-in-the-Loop Approach to Engineering Design (UILED). OpenMedLabs, which designs devices like insulin pumps and related accessories to ease the daily burden of people with diabetes, approaches prototyping as a non-linear process. “It’s not about finishing a stage and then testing,” Deval explains. “We constantly move back and forth.”

For example, when evaluating the usability of the insulin pump’s interface, they found that digital renderings fell short of conveying how the device would actually feel in users’ hands. “We needed a mock-up for users to hold, in order to ensure accurate feedback on portability,” he adds. They combined a physical mock-up with digital buttons on a screen to simulate the user experience. “It wasn’t ideal,” Deval admits. “But it helped people imagine how the final device would function.”

Make. Break. Repeat.

There’s a peculiar magic in watching a prototype fail – not in the tragedy of collapse or malfunction, but in the slow revelation of what went wrong. Perhaps a component just doesn’t hold, the texture simply feels wrong to touch, or a curve just feels a bit off.

‘It’s not always clear in the beginning where things will go wrong, but that’s why you prototype’

“Failure is a teacher,” says Arjun A, deputy manager at Titan Company. “It’s not always clear in the beginning where things will go wrong, but that’s why you prototype.” Arjun works in research and development, focusing on designing watch movements – the intricate mechanisms that dictate how a watch functions. At Titan, the movement and its variations are what distinguish one model from another, he says. Perfecting it requires countless iterations; the key is in treating every stumble as a signal for improvement. “The first version always fails in some way, but it’s how we pivot from there that counts.”

With Swiss premium watchmakers expanding into India and market forecasts projecting steady growth in the luxury segment through 2030, teams like Arjun’s are under pressure to move faster without compromising quality. His group is introducing AI automation into traditionally manual processes such as gear calculations and harmonic motion modelling to gain speed.

Vinay Reddy, co-founder and CTO of Sickle Innovations, which focuses on improving conventional farming practices through design interventions, concurs that failure is only a part of the process. “You may fail, and that’s okay. What matters is that you lead with knowledge. That is the only real level playing field,” he says. As an alumnus of DM, he reflects that students working in college labs often face resource constraints – like limited access to specialised equipment, budget restrictions, and tight project timelines – which shape the way projects unfold. “Resource limitations actually push you to design faster, lighter, and smarter,” he says.

Prototyping is never as smooth as it seems. It’s a crooked road, full of mistakes and discoveries. Foam, fabric, CAD – they all trip you up. Failure is not just expected, it’s part of the deal. It is feedback. You go back to the user, the materials, the purpose. You ask better questions, make smarter choices. But the effort can be worth it because in the end, like any good puzzle, it all starts to fall into place, piece by piece, until you’ve got something that almost feels like it was meant to be.

Spoorthy Kannur is a Master of Design student at IISc, and a science writing intern at the Office of Communications

(Edited by Abinaya Kalyanasundaram)