Unique centre at IISc’s Challakere campus exemplifies sustainable construction

The temperature was a sizzling 40°C on the morning of 24 April when I reached the IISc campus in Challakere. Summers in this area have become worse in recent years. The sweltering heat was becoming unbearable as I made my way past various buildings to reach the Centre for Bio-Energy and Low Carbon Technologies (C-BELT).

The gate leading to C-BELT is a sturdy 4.5 m wide structure, with a canopy allowing enough space for employees to park their two wheelers to escape the scorching sun. I noticed a group of people chatting under it. “It is cool and breezy here,” one of them said. That’s when I realised that it was indeed significantly cooler under the gate than the rest of the campus. The walls of the gate are made of stabilised Compressed Earth Blocks (CEB) with a jack arch roof, techniques that merge environmental consciousness with energy efficiency, producing structures that provide comfort to the dwellers.

Moving past the gate and coming upon the cluster of buildings that make up the C-BELT, I could not help being awed by the aesthetics of the construction. The earthy and rustic-looking, yet contemporary architecture was a marvel to behold. Despite the blistering heat, the buildings were cool and airy inside. All the buildings within the C-BELT are a standing example of the advantages offered by sustainable construction technologies.

The C-BELT project is an initiative of the Centre for Sustainable Technologies (CST) at IISc, which completes 50 years of its existence this year. Over its lifetime, CST has focused on developing low-carbon and energy-efficient technologies to bring about environmentally friendly, economically efficient, and socially responsible innovations, mainly in rural and peri-urban regions.

(Photo courtesy: CST)

In the last five decades, its researchers have worked on diverse areas including energy, buildings and habitats, solid waste utilisation, water and wastewater treatment, and more. This has resulted in the development of several sustainable technologies that have generated employment for communities across Karnataka as well as in many other states of the country.

Building on this legacy, CST decided to launch C-BELT in 2015 with an initial seed grant from the Department of IT-BT, Government of Karnataka, and later with CSR funds received from the HT Parekh Foundation. BV Venkatarama Reddy, then Chair of CST, and other faculty members spearheaded C-BELT. Reddy, Monto Mani (Professor) and SN Ullas (Senior Project Scientist), along with architect Mala Sugantha, led the construction of the C-BELT capacity building centre. It took two years to complete.

Reducing carbon footprint

There were two main objectives for setting up C-BELT at Challakere. The first was to have a permanent set-up where training and workshops can be conducted on sustainable technologies, which, until 2015 were being carried out at many different places, including the IISc Bangalore campus. The second was to build relationships with the villages and communities nearby, by constructing buildings that the latter required, like community centres and sanitation units using sustainable technologies. The CST team realised that such a space could help train the local communities to develop their own technologies. But they were not satisfied with just regular buildings that could house these activities. They wanted the buildings to be built using sustainable technologies, as a direct demonstration of their efficiency and to showcase CST’s own contributions.

“The deployment of sustainable technologies started right from building the campus boundary wall at Challakere,” says Reddy. About 4.5 km of the 10 km boundary wall of the campus has been built using rubble stones that were found in the arid land of the Challakere campus using a sustainable Random Rubble Masonry (RRM) technique. RRM involves the use of irregularly shaped stone boulders arranged randomly and packing the crevices with flowable earth mix mortar. The C-BELT buildings used climate responsive naturally conditioned building concepts with low-carbon materials. The impact of sustainable technologies is clearly evident – I did not spot a single air conditioning unit in the buildings of C-BELT.

The impact of sustainable technologies is clearly evident – I did not spot a single air conditioning unit in the buildings of C-BELT

The raw material used to build the Centre included locally available rocks, soil and gravel as an alternative to more polluting materials like glass and concrete. The Centre has several multi-purpose buildings that serve as demonstration units, showcasing how the use of low-carbon materials can create more habitable structures for visitors and trainees. One of these buildings is an academic and training complex which has a classroom, a laboratory, an office, an exhibition centre, a workshop demonstration unit, and a water storage unit. The residential area has a dormitory complex that can accommodate 30 people and a house for a caretaker.

“The premise was initially bustling with activity,” says Hemanthkumara R, a civil engineer who is in charge of maintaining the C-BELT infrastructure. “However, the pandemic has hampered the momentum,” he adds. Before the pandemic hit, two six day-long national-level residential training programmes were held.

Local and global impact

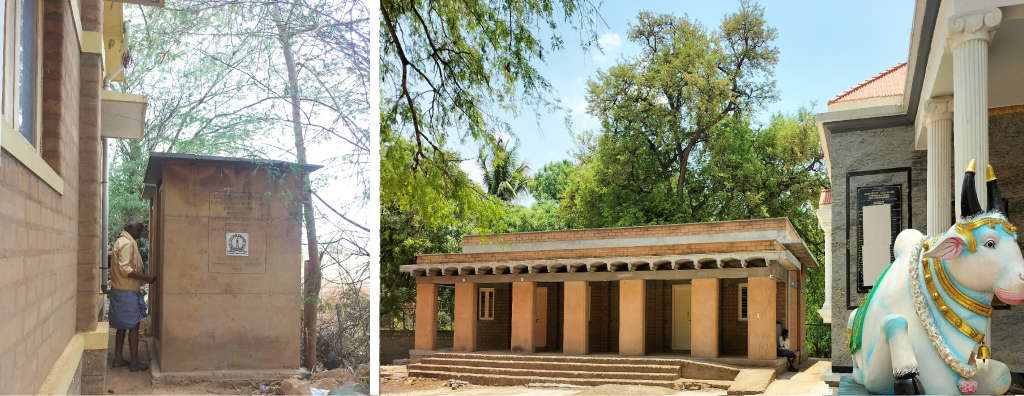

When IISc obtained the 1,500-acre campus at Challakere, the intent was to build relationships with local communities and give back something to the society, Reddy says. “We built community centres and sanitary units using pre-cast micro-concrete panels, and another type of sanitary unit using Flowable Earth Mix concrete. These are low-carbon sustainable and alternative methods of construction in these regions.”

Villages like Gouripura and Nayakanahatti located in the vicinity of the IISc Challakere campus benefitted from this. Many households in these communities were trained and provided with fuel-efficient biomass cook stoves called ASTRA ole. “We took some small contribution from the local people, not monetarily, but in the form of labour and some raw materials, so that they feel a sense of ownership,” Reddy adds.

Soon, the news spread in the vicinity and other villages too requested similar buildings. IISc has constructed about 20 sanitary units and four community centres in four villages so far. Several training programmes were conducted at the C-BELT. People who attended these workshops ranged from local farmers and villagers to engineers, architects and construction professionals, coming from far-flung regions like Uttarakhand and Chhattisgarh. Besides construction technologies and ASTRA ole, people are also trained in making devices like the ASTRA dryer, which is a dehydration device that facilitates drying fruits, vegetables and spices – this is particularly useful in damp and humid regions. Some participants have gone on to become entrepreneurs, manufacturing and selling their own versions of these devices. Water treatment and removal of fluoride from water is another very popular training programme conducted at C-BELT.

With the threat of climate change accelerating across the world, there’s an even greater need to expand the use of such sustainable technologies.

Non-renewable resources like soil, metal ores, chemicals, limestone, oil and gas are fast depleting because of indiscriminate mining. The construction industry is a particularly notorious polluter, consuming about 45% of all natural resources and contributing heavily to the rising carbon emissions.

The sustainable technologies developed and demonstrated at C-BELT provide a viable alternative to this carbon-intensive contemporary construction. Besides the RRM method, other sustainable building technologies that they have developed include cement-stabilised Compressed Earth Blocks (CEB), stabilised earth mortar, filler slab roofs, cavity cool roofs, stabilised rammed earth, and so on.

For example, the CEB is a high-density (>1.8 g/cc) block, manufactured by compacting earth or compressing a partially saturated processed mixture of soil, sand and stabiliser. They are produced from natural materials, primarily soil, which is abundant and renewable. Their production requires minimal energy compared to traditional building materials like bricks or concrete, reducing carbon emissions associated with manufacturing. The machine that produces CEB employs a static compaction process. These machines were designed from scratch by CST researchers. The adoption of sustainable technologies not only calls for efforts of researchers, but also requires policy support, public awareness campaigns and market incentives. Reddy says that the Centre is currently seeking funds to sustain its maintenance and increase the scope of its activities.

Most of the technologies being developed at C-BELT are not patented, so that they can be freely disseminated

Notably, most of the technologies being developed at C-BELT are not patented, so that they can be freely disseminated to everyone. Care has also been taken to ensure that these technologies and products stand the test of time.

Reddy recalls an incident about 12 years ago, when there were heavy rains just after the boundary wall was erected around the Challakere campus using RRM. Some of the personnel there were unsure whether the wall would survive the downpour as they had used an unconventional method to build it, using minimal cement and rubble stones. Not only did the wall withstand that torrent but it has also remained steadfast for more than a decade. In recent years, many architect visitors have adopted this technique to build commercial and residential buildings.

Sustainable technologies, at their core, seek to conserve nature and mitigate climate change. It is only prudent that these technologies are increasingly implemented to counter the environmental degradation that has happened in the recent past. C-BELT is an illustrative example of how sustainable technologies can merge charm and aesthetics with energy efficiency and cost effectiveness.