Geotechnical engineers, who investigate soils and their properties, play an important and sometimes overlooked role in civil engineering

A vacation on a Spanish beach in the 1960s sparked a revolution in the construction industry.

French engineer Henri Vidal was piling up sand to build a sand castle when he realised that no matter how hard he tried, he could not make the angle of the mound steeper than its natural incline. This is because sand, like all soils, has poor tensile strength – it comes apart easily as the individual particles don’t cling tightly to each other. But when he stuck pine needles into the sand, he found that the friction between the needles and sand helped stabilise it and allowed him to make steeper mounds. Excited by this discovery, he went on to develop a construction technique and later a multi-billion-dollar company called “Reinforced Earth” that changed the way many modern structures are built.

The idea was simple: If you alternate layers of soil with strips made of materials like steel, you could make the layers strong enough to build walls, bridges, even dams. Since the 1980s, engineers have switched from steel to polymers called geosynthetics that are more lightweight, cost-effective and corrosion-free. Today, thousands of structures are being constructed with such polymer-blended soils using the reinforced earth technique.

“Even the engineers building the new airport terminal in Bangalore are using this technique for expanding the access roads,” says G Madhavi Latha, Professor in the Department of Civil Engineering at IISc. “If you see most of the abutments of bridges or flyovers these days, from the outside, they all look like [they are made of] concrete, but inside it is all soil.”

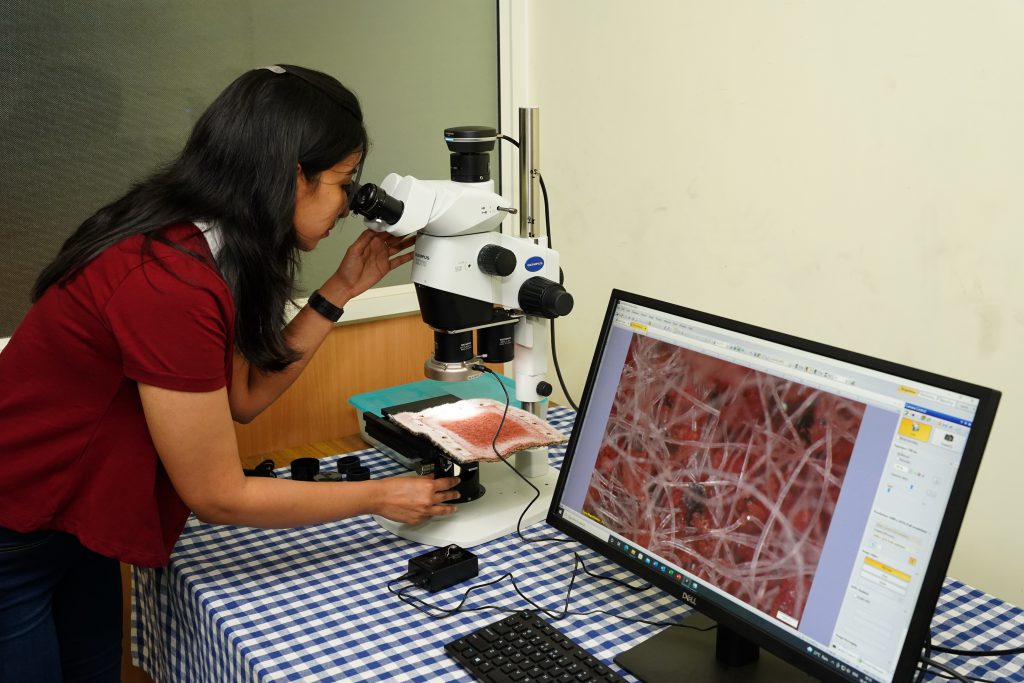

Madhavi’s lab studies reinforcement techniques using a variety of sophisticated instruments. With a universal tensile testing machine, they are able to stretch geotextiles – fabrics made from polymers – to test their tensile strength, the maximum load they can support when stretched. A 3D printer helps them print not only geosynthetics but also sand particles in desired shapes, sizes and textures using polymers. One of her PhD students, Rizwan Khan, is using video cameras set up in the lab to track how the interfaces between different soil layers, and between soil and geosynthetic layers, behave as they rub against each other. Madhavi is particularly proud of the digital microscope she has set up that helps her students peer at the tiniest of grains in a soil sample. Such digital imaging-based explorations, she says, have brought a lot of “freshness” and innovation to the more traditional field of civil engineering.

“When you say civil engineering, people think of huge structures like dams or buildings,” points out Raghuveer Rao Pallepati, Principal Research Scientist at the Department of Civil Engineering. “All these structures have to rest on the ground. How good the ground is to support the structures is assessed by geotechnical engineers.”

“When you say civil engineering, people think of huge structures like dams or building. All these structures have to rest on the ground”

Geotechnical engineers like Madhavi and Raghuveer are fascinated by how various soils behave under different conditions. Soils are classified into different types – clay, silt, sand or gravel – depending on the fraction of the different-sized particles that they contain. With concrete now being recognised as the most destructive material on the planet, soil is rapidly making a comeback as a construction material. Soils with clay-sized particles are also being explored as liner materials to stop leaching from landfills and hazardous waste pits. Crucially, soil is at the heart of many natural and climate-change induced disasters – its collapse can bring buildings to the ground and lead to landslides and flooding.

“Superstructures like concrete buildings are [made of] manufactured materials. We know their properties and we can control them,” says Raghuveer. “But the ground is naturally formed with different-sized particles, mineral content and conditions. We have no control over that.”

On solid ground

If you take a spoonful of sand and sugar side-by-side, you might think that the individual particles are of the same size. This is true for sugar, but not sand, explains Raghuveer. Soils are an uneven mix of particles of different shapes and sizes. The texture and colour of the soil varies depending on the type of material that weathered over millions of years to give rise to it. A soil patch in the IISc campus is usually red in colour because of minerals rich in iron, whereas the cotton-growing soils found in North Karnataka’s Gulbarga and Bidar districts are pitch black due to the presence of iron and aluminium as well as the soil’s ability to retain a lot of water.

This variability is a major reason why soils “cannot be taken for granted,” says Sudhakar Rao, former Professor in the Department of Civil Engineering. If you dig up the soil at a specific spot, and then dig at another site just 100 metres away, there is no guarantee that the composition will be the same, he explains.

Another important feature of soils is how much water they can retain, called the level of saturation, which determines their ability to support structures built on top of them, like buildings or walls.

“Imagine you have constructed a structure when the soil was unsaturated [devoid of water],” says Raghuveer. When it rains and the ground water level rises, filling the air pockets between the soil particles, the weight exerted by the structure on the ground will initially be taken up by the water, which forms an interconnected matrix inside the soil. Later, when the water dries up, the weight gets transferred to the soil particles, which causes them to deform, and makes the building “settle”, developing cracks or sagging floors. “In the lab, we can estimate and extrapolate how much will be the settling for a building over time, before construction begins,” he explains.

Some expansive soils, like the black cotton soil, swell when they are in contact with water during the rainy season, and shrink during the summer as the water evaporates from the ground surface, adds Raghuveer. “If you construct buildings at a shallow depth in North Karnataka, most of them will get cracks. To prevent that, you have to rest the foundation at a depth where the moisture changes are minimal.”

Soil stability is especially critical when it comes to earthquakes. When tremors travel through the ground, the shockwaves loosen and separate the soil particles, making the soil flow, almost like a liquid – a process aptly called liquefaction. Two of Madhavi’s students, Balaji Lakkimsetti and Prerana Krishnaraj, are currently creating earthquake-like conditions in the lab using cyclic simple shear and shaking table experiments, and trying to understand how soils liquefy and how they can be strengthened to withstand various degrees of shaking.

geocomposites that can reinforce pavements (Photo: Prince Kumar)

With advances in technology in recent years, even the weakest of soils can be reinforced before constructing any structure. “If you look at the Burj Khalifa, people never thought about the fact that it is so close to the sea, that marine soils have a lot of problems,” says Madhavi. “Because there are solutions which can make soils take any amount of load.”

One of those solutions is using geosynthetics, like the polymers in the reinforced earth technique. Geogrids, for example, are rectangular mesh-like structures that can strengthen the aggregates used for roads and pavements, and reduce the thickness of the layers paved. For a 100 km-long road, reducing the height by one-fourth of a metre can save a few thousand tonnes of natural soil, Madhavi explains. A large cyclic triaxial setup in her lab – the only one of that size in the country – helps her study the strength of these reinforced aggregates under simulated vehicular loads.

Such geosynthetics can also be made from recycled materials. Kalore Shubham Arun, a PhD student in the lab of Sivakumar Babu, Professor in the Department of Civil Engineering, is using geocomposites produced from crude oil waste to design improved pavements that can help drain water faster, and prevent water logging and potholes. “Not much research has gone into this area for Indian conditions,” he says, adding that results from such studies can contribute to road and highway management policies.

With land space becoming scarce in cities like Bangalore, such reinforcement techniques are only gaining momentum.

“Earlier, if you found a piece of land that was not conducive to construction, you could ignore it. Land was available in plenty. Now, it is no longer that situation,” says Sudhakar.

Sudhakar, who has studied soils for decades, also laments the loss of many traditional practices that involved using soil for construction. Centuries ago, villagers in North Karnataka used to mix the black cotton soil with grass, hay and cow dung and let it age for decades to build strong walls for their houses. “We went to those sites, brought these samples to the lab and examined them to figure out how the villagers did it. We got some interesting results,” he says. But the practice has long since been abandoned, and none of the local people the team spoke to was able to remember what their ancestors used to do. “Unfortunately, with the advent of easy construction technologies, people forget about these things.”

converted to geopolymer sand (right) to use in construction (Photos: Indra Prasad Acharya and Sudhakar M Rao)

Leaks and landfills

In the late 1990s, a few years before Sudhakar started working on the black cotton soils, many countries were waking up to the looming problem of disposing nuclear waste safely. For highly radioactive waste, the plan was to bury them deep into the bedrock (more than 1-2 km below the surface) in canisters made of steel or a similar strong material. But what if this steel cracks, and radioactive waste begins leaching into the ground, making its way to the groundwater? The answer lay in a type of clay that you might find in your acne face mask – bentonite. Bentonite is nearly impervious to water and has excellent self-healing – it can absorb liquids that may leak, and swell, plugging any holes or punctures. It can also remain stable for millions of years. Bentonite blocks surrounding the steel canisters can therefore provide a rugged and long-lasting barrier.

“We had a project with the Board of Research in Nuclear Sciences to identify the type of bentonite that could be used for a high-level waste repository,” recalls Sudhakar. “We scouted around the country, identified a type of bentonite in a place called Barmer in Rajasthan, brought the soil to the lab and did a lot of tests to evaluate its usefulness as a waste containment material. The lab was very successful in identifying, characterising, and comparing it with bentonites in other countries.”

While such repositories are still way off into the future, a more immediate challenge is staunching leaks in urban landfills. Anjali Pillai, a PhD student in Madhavi’s lab, is trying to figure out how a combination of a material called geosynthetic clay liner (GCL) – which contains bentonite at its core – and M-sand – artificial sand made from crushed rocks like granite – can be used to line landfill slopes. “Sand mining is illegal now, and causes a lot of environmental problems. Instead of sand, we can lay this material as the bottom-most layer to line landfills,” she says. Anjali is particularly interested in understanding how efficiently the M-sand particles interact with GCL. This ‘interfacial strength’ is important because many landfill failures have been linked to poor interactions between the various layers that line its slopes. “Once you prepare [the landfill], there is no going back, because its lifespan can be 30-50 years,” she says.

microscope to study the interaction between geosynthetic clay liner

and M-sand particles (Photo: KG Haridasan)

Some geotechnical engineers are not only interested in building such landfills but also in managing the waste inside them. “Solid waste ultimately degrades into a soil-like material … that’s the reason why we apply the same principles of soil behaviour to it,” explains Sivakumar Babu. Several of his students are working on various aspects of landfill management. “We have 300 acres of dumpsites in Bangalore … there are significant problems like leachate, methane emissions, and water contamination. We have to solve these problems as well.”

“If you visit any landfill in Bangalore, you rarely find any that have a proper lining system. Most of them are not engineered,” says Prince Kumar, one of his PhD students who is working on models to estimate the amount of toxic gas generated from landfills, and design effective gas extraction systems. Another student, Anusree N, is focusing on ways to enhance the breakdown of materials in landfills by using natural enzymes. “Waste management is an area in which people are usually hesitant to work,” she says. “At the same time, this is also one of the most burning issues.”

Saving soil

The image of a burning Bellandur lake is something that Bangaloreans have become uncomfortably familiar with in recent years.

But it is not the only area in the city where both water and soil are being polluted by effluents from industries. Soil pollution, a serious issue in many urban areas, is also something that people like Sivakumar Babu are working on. Two of his students, Kalyani Kulkarni and Prathima Basavaraju, have been collecting soil samples from the Bellandur lake area and Peenya industrial district to determine the levels of pollutants like chromium, nickel, cadmium and zinc, and come up with ways to reduce them. “Chromium contamination is one of the more serious problems as it is carcinogenic,” says Sivakumar Babu.

“When these heavy metals are in the soil, they enter the crops and then the food chain,” explains Kalyani. The goal, therefore, is to convert the metals into forms that are less available to plants, either using compounds that bind to and stabilise them, or precipitate them out of the contaminated soil. Some nanoparticles they are testing in the lab, for example, can convert the more toxic form of chromium (hexavalent) into a less toxic form (trivalent). “Soil chemistry is quite complex. Every metal reacts differently to the same remediation method,” Kalyani says.

Sivakumar Babu’s lab is also interested in landslides, a recurring disaster in several parts of Karnataka which receive heavy rainfall. The reason why civic authorities are unable to effectively prevent and manage landslides is due to a lack of understanding of soil behaviour, he says. His lab has been exploring the use of various geosynthetics like geotextiles and geogrids, which can hold the topsoil in place and reduce the impact of landslides.

“We can also use sensors to track and predict what could be the soil movement during landslides, and forewarn people,” Sivakumar Babu says. “[But] at the same time, the response from government agencies is not very effective. They say, ‘Let the problem come, we will solve it later.’”

Raghuveer echoes this sentiment. Most of the government or private contractors he consults for call him only for “forensic” analyses, to try and figure out what went wrong after a building or structure has collapsed. He highlights the example of a major research facility that was recently built by a governmental agency, which began developing water leakage in the basement due to lapses in soil investigations and design of the foundation. Many “settled” buildings across Karnataka and slope failures due to rainfall – such as one that his PhD student Vibha S and MTech student Mohit Jadav are currently investigating in Chikkamagaluru district – could have been avoided by proper site investigation, analysis and design, he says.

“Unfortunately, people pay a lot of attention to the elevation of the building. They will pay the architect a lot of money and ask them to make it look nice, but they will not be willing to pay a geotechnical engineer to do the site investigation. But once it goes out of control, they will come to us,” he says, with a chuckle.

“Our accomplishments are not visible outside, but they are very important,” Raghuveer says. “Everyone says you need a strong foundation. That strong foundation is built by geotechnical engineers.”