Several researchers at IISc are working on technological solutions to tackle some of the causes of climate-induced disasters, and reduce carbon emissions

A sizzling heatwave across North India, prolonged power outages, and 20 million dead. Fortunately, this is a work of fiction, the setting in the first chapter of The Ministry for the Future, a novel by Kim Stanley Robinson. If you thought that this was a news headline, you are not far off from reality. Severe heatwaves hit India and Pakistan earlier this year, leading to the hottest recorded temperature in March since 1901. In the past few years, there has been a steady increase in the number of such extreme weather phenomena, taking lives and livelihoods. From recording-breaking snowfall to extreme flooding, all these can be attributed to climate change and an increase in the global mean temperature.

The predictions outlined in the 2022 IPCC report – published by the Intergovernmental Panel on Climate Change, a UN body tasked with tracking climate change – are extremely alarming. As one of the developing countries in the tropical region, India is set to be among the most affected by climate change. The dominant contributors to global warming are developed countries in Europe and North America, says J Srinivasan, distinguished scientist and former Chair of the Divecha Centre for Climate Change at IISc. “If we want to solve this problem, these developed countries need to ensure that the technology for shifting to renewable resources must be easily available and must be funded by them partly,” he adds.

However, as one of the most populous countries, India cannot afford to rely on developed countries alone and needs to step up its own efforts to mitigate and adapt to the impacts of climate change. The Indian government has set ambitious goals for achieving an energy capacity of 500 GW from renewable sources by 2030 and net-zero emissions – cutting down greenhouse gas emission as close as possible to zero – by 2070. But achieving these goals is not easy; it needs technological innovation and intervention on a large scale.

“Climate change has been a crisis in the making for the past few decades, and we need efforts on a war footing,” says Srinivasan.

IISc researchers are no strangers to technological innovation. From microelectronic technologies to water purification, they have been working on many socially-relevant as well as futuristic solutions. For example, a new quantum technologies initiative has recently been started to bring together researchers in various disciplines to make quantum computing a reality. Researchers in electrical, electronics and computer sciences are pioneering 5G technologies.

During the COVID-19 pandemic, many innovations were developed including ventilators, oxygen generators and sanitisation devices. Like these efforts, developing sustainable technologies aimed at reducing the carbon footprint and building a sustainable future has also been a major focus. Many researchers at IISc have been working on diverse technologies to help battle climate change – from solar cells and electric vehicles to bioplastics.

Bioplastics and alloys

Every year after the harvest season, in the months after September, fires rage across fields in North India. These fires are intentionally set to burn the stubble on farms after the grains have been harvested. The resulting air pollution has significantly affected the air quality index in Delhi and other adjoining regions. Its proponents argue that stubble burning is necessary to remove the crop residues. But is burning the only solution to get rid of them?

Researchers at IISc have recently found a way to convert this stubble into bioplastics – plastics that can be made from organic sources. The team, led by Kaushik Chatterjee and Suryasarathi Bose, associate professors at the Department of Materials Engineering, and including Indranil Chakraborty, a research associate, has come up with a process that converts the cellulose in the stubble to a plastic-like material that can be reused.

Researchers at IISc have recently found a way to convert stubble into bioplastics

Currently available bioplastics are based on starch and their manufacturing processes involve the use of certain catalysts. They also require specialised enzymes and processes for degradation. Unlike these, the ones developed by the IISc team are made using processes that do not require harmful catalysts like BPO (benzoyl peroxide). These bioplastics are completely degradable and are not expected to affect the environment by producing harmful chemicals when buried under the ground.

“There are no byproducts from this process. We use precursors from oils and certain things from the stubble and combine these two to make a plastic,” says Suryasarathi. This process is also scalable. Starting with a few grams, they have now been able to produce many kilograms of bioplastics in the lab. Currently, these plastics are awaiting certification and are being tested for their mechanical strength. The team is also checking to see what products these bioplastics degrade into. “Since the precursors are organic, we are hopeful that the final products, on degradation, would also be organic, something like carbon dioxide or water, something which can be safely released into the environment,” adds Kaushik. Using the stubble to produce bioplastics not only provides the farmers an additional source of income, it also reduces carbon emissions while providing alternatives to commonly used plastics.

and cellulose (Photo: Indranil Chakraborty)

Another innovation that has come out of the department is the development of magnesium and titanium-based alloys which can help reduce carbon dioxide emissions. Aircrafts and other automobiles use aluminium alloys since they are resistant to corrosion and have a high weight-to-strength ratio, thus making aircrafts light and efficient. Yet, air travel continues to be a major contributor to global warming. In multiple labs at the department, researchers have been working for many years now on magnesium and titanium-based alloys as alternatives to aluminium. These alloys have great potential to make automobiles and aircraft fuel-efficient by making them lighter than they are now and reduce carbon emissions.

Satyam Suwas, Chair of the department, has been leading efforts to make magnesium-based alloys a reality. These alloys are known to be stronger and lighter than steel and aluminium. “Magnesium alloys are anisotropic – on deformation they expand differently in different directions. Our focus was to reduce this anisotropy, so that the components made using this alloy will be perfect and would serve their purpose,” he says. Another drawback is that magnesium alloys are not ductile enough to be made into parts, and that’s also a challenge that the researchers at IISc are currently working on.

Electric vehicles

Just like the aviation sector, the transportation sector is also a major contributor to carbon dioxide emissions – around 23% of the total emissions in 2010, for example, according to the IPCC. Governments of many countries have been pushing for the adoption of electrical vehicles (EVs) with the goal of adopting a ‘cleaner’ method of transportation, and reducing emissions. But as much as they are touted as being ‘zero-emission sources’, they aren’t really so if the source of the electricity supplied to such vehicles is itself not green. A major fraction of electricity supplied to cities is still from either coal power plants or other carbon emitting sources. In India, as of January 2022, renewable energy stands only at 38.56% of the total capacity. Continuing to use electricity from standard power sockets to charge your EVs does not technically reduce carbon emissions to zero.

(Photos courtesy: Ashish Verma)

However, one way to really achieve zero emission transport is to power the charging stations using renewable sources such as solar panels. Researchers at IISc have been testing the viability of setting up such zero emission EV charging points. Ashish Verma, Professor at the Department of Civil Engineering, and his team have set up one such charging point on campus behind the JRD Tata Memorial Library. Over a year, they tracked how much power was being collected and stored by the charging point and how frequently it was being used. The study, which was launched as an Indo-UK joint initiative, reported some positive results, and moreover was very well received by the IISc and Bangalore community, Ashish says. Many IISc community members had even purchased EVs with the reassurance that they could charge their vehicles on campus. But once the study was completed, the charging point was discontinued. “Many members of the community wrote to me enquiring about the charging point, expressing their disappointment on finding out that it was closed,” says Ashish. Given the overwhelming response, he is currently working with the Institute administration to scale up the charging points on campus.

But just one such point isn’t enough. Would people buying EVs be able to find enough charging points across the city and state, and be able to make long-distance rides without worrying about running out of power? This is one of the challenges that Ashish’s lab is trying to address. They have developed computer simulations and methods to optimise the locations where EV charging points can be installed after taking into account various factors, including the load on the power grid, usage, and population. Ashish and his team have been working closely with BESCOM, the government agency in charge of electricity supply in Bangalore, to set up optimal charging points and grid modifications.

One way to really achieve zero emission transport is to power EV charging stations using renewable sources such as solar panels

The road for EVs has not been smooth so far. In the past few months, there have been various reports of EVs catching fire. Ashish says that while adoption might be hampered temporarily due to such incidents, he expects that the technologies will “mature” over the next 10 years, by which time more people would be more willing to adopt them. He argues that now is the right time for all the stakeholders to come together and set down ground rules for these technologies – standards for battery shapes and sizes, battery swapping policies and other battery-related needs.

Organic solar cells

EVs are only recent entrants in the energy race, but solar power-based energy generation has been around for several decades. Even though solar energy is considered a purely ‘green’ source, manufacturing solar cells can be both resource and energy intensive.

First and second generation solar cells that are currently available in the markets are silicon-based and India does not have large reserves of silicon, leading to large imports and reliance on other countries. In the year 2021, silicon imports cost our country about USD 3.5 billion, with nearly 90% of the material coming from China, according to Mercom India Research, a clean energy communication and consulting firm.

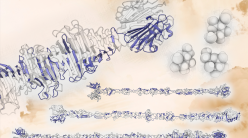

“To fully harness the potential of sunlight and reach the goals of sustainable energy for all, solar cells made with organic and perovskite materials are key players,” says Satish Patil, Professor at the Solid State and Structural Chemistry Unit at IISc. He, along with other researchers at IISc, is working on enhancing the efficiency of organic and perovskite-based solar cells. These solar cells, which mimic the green leaves of plants that carry out photosynthesis, use photosensitive organic chemicals and polymers for light absorption and charge transport in order to produce electricity. They offer the promise of being less expensive, more flexible, thinner and more amenable to a wide range of lighting conditions, all of which make them suitable for a host of applications beyond rooftop and solar-farm panels, Satish says.

Chemistry Unit, IISc (Photo: Manasi Venkatramani)

Currently, Satish’s team has been able to achieve 17% power conversion efficiency for these organic solar cells. A major challenge in developing organic solar cells is their lifetime and durability, which depend on the stability of the molecules used. His team is currently evaluating several candidate molecules for their stability and efficiency.

Another challenge is integrating solar panels with greenhouses. Organic solar cells are particularly attractive, because their light-absorbing capacity can be tuned, and they are inexpensive, thin and light-weight.

Unlike silicon-based solar cells, the main advantage of organic photovoltaics is that they can be made semi-transparent. These solar cells can be installed above existing agricultural lands and greenhouses. The organic molecule is chosen such that the panels allow light that the plants require to pass through and absorb light from other parts of the visible light spectrum.

“Making dual use of the land has several benefits, both in the context of climate change and economical benefits for the farmers,” says Satish, whose team plans to develop such semi-transparent cells.

Miles to go, and time too short

The ultimate question, however, is whether such innovations that happen inside the labs of IISc are enough to combat climate change on a large scale. Srinivasan says that while various scientists are doing their part in developing new technologies and improving existing ones, many of these technologies take years to materialise in the markets. He also stresses the importance of collaborations with industries as a driving force for research. In fact, the early efforts to study and develop magnesium-based alloys by Satyam and his colleagues at IISc was first initiated and funded by General Motors, who wanted magnesium-based alloys to manufacture lightweight parts for their automobiles.

Srinivasan also believes the current academic system needs to be revamped so that it rewards researchers who work on socially-relevant issues such as sustainability.

Climate change is a “problem that transcends generations,” as scientist and educator Carl Sagan put it, requiring efforts that are both large-scale and long-term. And time is running out to initiate them. “We have been using fossil fuels for more than 100 years and now we need to reduce carbon emissions to zero within the next 30-40 years. Unfortunately, right now, in most countries, leaders cannot plan beyond 10 years,” says Srinivasan.

During World War II, the US civilian industry was completely overhauled to make vast quantities of military equipment in an exceedingly short time frame. But such organised efforts shouldn’t wait until 20 million people lose their lives in a heatwave.

Praveen Jayakumar is a former Master of Science student at IISc and a science writing intern at the Office of Communications