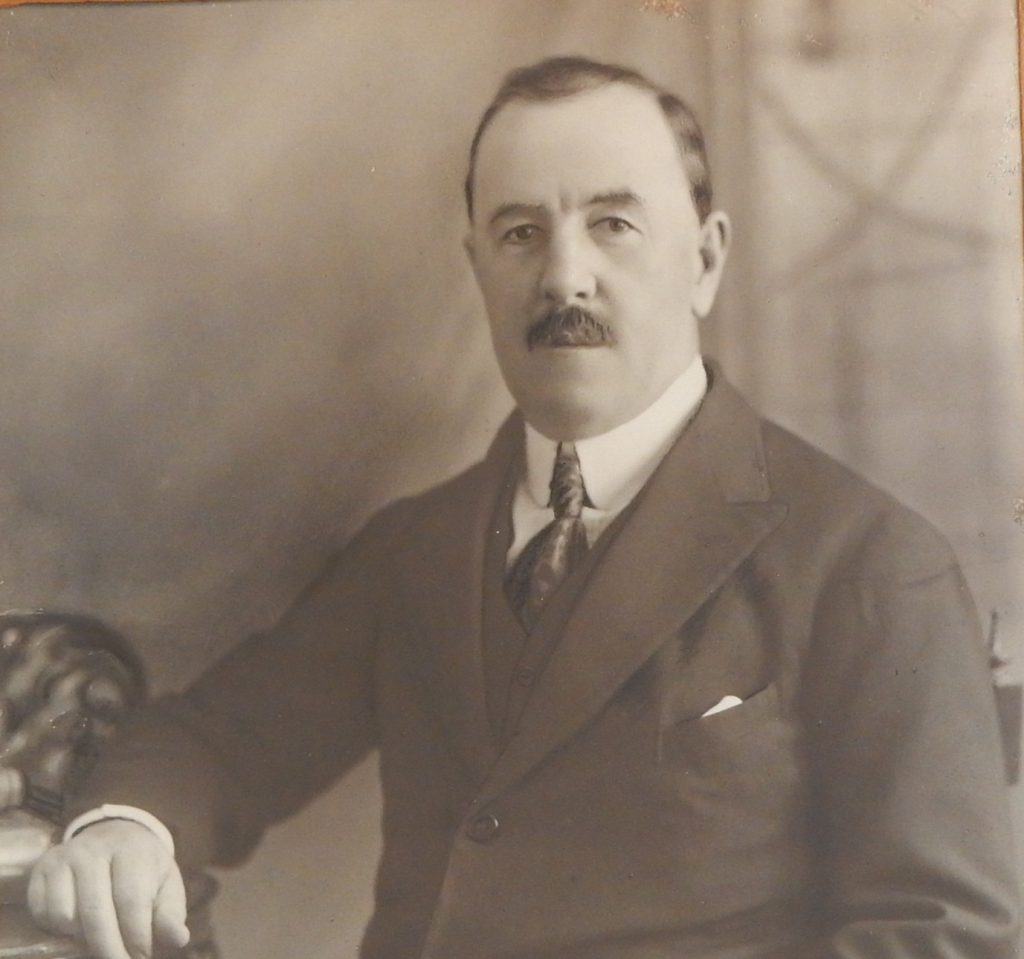

The first head of the Department of Biochemistry was one of the most consequential researchers of his time

Gilbert John Fowler wore many scientific hats: he was a chemist, a biologist and an environmental scientist – decades before environmental science became an active field of scientific investigation. He even fancied himself as an economist. And he often wore these hats at the same time, making him a practitioner of what one would call interdisciplinary research today. He was also a prolific scientist, undertaking and supervising numerous investigations on a wide range of topics, publishing several papers (and books), lecturing extensively, and serving as a consultant for a number of industrial and municipal projects in India and abroad. Furthermore, many of the studies he carried out at IISc were considered important enough for them to be continued, both at IISc and elsewhere, long after he retired. Perhaps most significantly, much of his science was rooted in the problems that he saw around him. Fowler was, as his record shows, a scientist’s scientist.

Before IISc

Born in Paris on 23 January 1868, Fowler obtained an undergraduate degree in chemistry in 1896 from the Victoria University of Manchester, UK. Three years later, he received a Master’s degree from the same institution, and for his thesis, which was in metallurgy, he was given the Dalton Prize. He continued at the varsity, where he was first appointed as a demonstrator and then a lecturer. During this period, he also served as a consulting chemist to the Rivers Committee of the Manchester Corporation. He remained a Mancunian until early 1916 and made a name for himself by helping to treat the sewage and trade effluents of Manchester, then the textile capital of the world. In 1904, he was awarded a DSc degree from the University of Heidelberg, Germany, for his work on sewage purification.

In 1915, Fowler applied for a vacant position in IISc. His application was successful, and in February of the following year, he arrived in IISc to take charge as a professor and the de facto head of the Department of Applied Chemistry, one of the only four departments in the Institute at the time (the others being the Departments of General Chemistry, Organic Chemistry, and Electrical Technology). In 1921, when IISc decided to start a department to focus on the relatively new field of biological chemistry, it did not have to look beyond Fowler to lead it.

Much of Fowler’s research was rooted in the problems that he saw around him

Acetone

When Fowler joined IISc, the world was in the throes of an armed conflict that eventually came to be known as World War I. India was not untouched by the war. By virtue of being part of the British Empire, it sent over a million of its soldiers to the trenches. The imperial government also looked into other ways in which India could contribute to Britain’s war effort. One of them, it believed, was in the manufacture of acetone, a colourless organic compound that most of us are familiar with as nail polish remover or white board cleaner. It was also the main ingredient in cordite, an explosive that was used by the British Army during WW I as a substitute for gunpowder. So the government decided to set up an acetone factory, and for the scientific expertise required to manufacture it in large quantities, it turned to IISc.

Cordite filaments in a .303 British Rifle cartridge

(Photo courtesy: Forrest H Barfield/Wikimedia Commons)

As soon as Fowler was hired by the Institute, he was tapped for the acetone project by the government – even before he left Manchester. So when he boarded the steamer to travel to India, he carried with him a stash of bacteria, the “Weizmann bacillus”, for the fermentation of acetone (the bacterium, whose scientific name is Clostridium acetobutylicum, was first isolated by Fowler’s colleague at Manchester, the Russian-born British biochemist Chaim Weizmann, who later renounced his British citizenship and became Israel’s first President).

Once Fowler arrived at IISc, he hit the ground running to make acetone. He, along with research scholars YD Wad and AG Gokhale, first set up an experimental unit that could be replicated on a larger scale at the Government Acetone Factory being built in Nasik in the Bombay Presidency. A temporary office for the factory was also established at IISc in Bungalow No. 9 and Fowler was appointed as a Consulting Advisor for the factory.

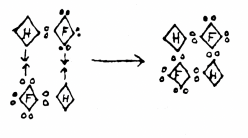

Until Fowler’s work on acetone in IISc, it was made mostly by distilling wood. But this was an inefficient process. Fowler’s team therefore began working on fermenting starch-rich substances like rice using the bacterial culture he brought with him. The bacteria degraded starch to produce organic solvents, which when distilled left behind pure acetone. However, they needed to find a cheaper source of starch. Initially, they spent a considerable amount of time and resources on fermenting the flowers of the mahua tree, but the amount of starch in them was not sufficient to make the huge quantity of acetone that was required.

Eventually they discovered an inexpensive raw material that could also produce an impressive amount of acetone: jowar. Following this discovery, the vats and other equipment were dismantled and the technology was transferred to the Nasik factory, where Wad and Gokhale were appointed as staff.

The acetone project was Fowler’s main focus during his first two years at IISc. But when it ended, he had the time and freedom to pursue investigations on other natural products with greater vigour. One of them was on mahua, which had already been studied as a potential raw material for acetone fermentation.

Mahua

Mahua is a fast-growing tropical tree common in the plains of Central and North India. Its fruits and flowers have traditionally been used as food and for making medicines and country liquor by Adivasis. When Fowler began his studies on mahua, it drew the attention of the Nizam of Hyderabad who sponsored five research students to work with him at IISc. To carry out these studies, the Nizam would send flowers week after week to IISc. Within a year, however, Fowler’s team found a few mahua trees in IISc’s vicinity and the Lal Bagh Botanical Garden in Bangalore.

The most significant investigations into the mahua flower involved understanding the factors that determine the yield of alcohol when it is fermented. These included the composition of mahua decoction, kind of yeast used, temperature, and other growth conditions. One research student, Habib Hassan, also studied the possibility of making the decoction (which according to IISc’s 1917 Annual Report has an “unpleasant” smell and taste) into a syrup for use in cooking and in jams. He succeeded in making it more palatable, says the Report, using lime and charcoal. Edal Behram, another student in the department, studied the developmental biology of the flower, and its biochemistry to understand how sugars are formed. Fowler’s team also succeeded in extracting essential oils from the flower and even explored the possibility of using mahua sugar as an alternative to cane sugar.

Mahua flowers (Photo courtesy: Gypsypkd/Wikimedia Commons)

Lac

Yet another natural product that interested Fowler was lac, produced by a group of scale insects. It is secreted by the larvae of these plant bugs after they feed on the sap of specific host trees. It has been used in India for centuries – as a seal, dye, and wood finish, and also to make cosmetics and bangles.

Lac became popular in Europe in the early 20th century because shellac, its processed form, became indispensable in the manufacture of gramophone records. It was also used in ammunition, paints and varnishes.

Fowler worked with two gifted research scholars on lac at IISc: S Mahdihassan, an entomologist, and M Sreenivasaya, a biochemist. Several other students also became involved in the lac-related lab experiments and field studies that were carried out in and around Bangalore. Their research was enormously productive. In less than two years, IISc became the hub of lac research in India, as Debi Prosad Burma and Maharani Chakravorty note in their book From Physiology and Chemistry to Biochemistry. Research on lac at IISc not only resulted in several publications but also led to the setting up of the Indian Lac Research Institute in Ranchi by the government in 1924 (it still exists but has been renamed as the Indian Institute of Natural Resins and Gums). It was headed by Dorothy Norris who briefly taught chemistry at IISc. Burma and Chakravorty also write that the staff at the newly established institute was populated almost entirely by researchers who migrated from IISc.

The activated sludge process

Though Fowler had his fingers in many pies during his research career at IISc, which lasted for more than eight years, he never forgot his first love: the activated sludge process, which he is credited with developing. In 1912, he was invited to the United States to address the growing contamination of the East and Hudson rivers. During his visit, he had been shown some experiments which involved forcibly aerating wastewater to treat it. “These were not entirely successful, and it appeared to him that the correct type of bacteria was not present,” writes HE Watson, his colleague at IISc, in an obituary for Fowler published in the Journal of the Chemical Society.

Back in Manchester, Fowler convinced Edward Ardern and William Lockett, engineers at the Rivers Committee of the Manchester Corporation, to carry out similar experiments. But in these studies, they retained the precipitated sludge. “This sludge proved to be the home of the missing bacteria, and the activated sludge process, perhaps the most important in the world today, became a commercial possibility,” Watson adds. (In 1942, in a paper in Nature, SC Pillai and V Subrahmanyan from the department demonstrated the role of ciliated protozoans as well in the process.)

(Photo courtesy: Unknown/Wikimedia Commons)

When Fowler moved to IISc, he continued his work on wastewater treatment. He was invited to several cities in India and around the world to help set up plants based on the technology developed at Manchester. Burma and Chakravorty write that, “Between 1925 and 1953, he [Fowler] was responsible for about a dozen activated sludge plants of different sizes in different parts of India.”

In 1922, Fowler also designed and built an activated sludge treatment plant in IISc. Besides dealing with the sewage on campus, it allowed for many experiments to be carried out in the Biochemistry Department. The most valuable insight that Fowler obtained from these studies was that the sludge, rich in nitrogen, could be used as an organic fertilizer and a feed supplement for poultry. At IISc, he also developed a method to separate the solids and liquids in sludge in sewage treatment, a process he patented in 1935.

Fowler is credited with developing the activated sludge process

Towards the end of his research career in the Institute, a related area of study that Fowler became fascinated by was composting. Like the active sludge process, composting is a way of recovering nitrogen from waste for use in agriculture. “As time went on, it became clear to him that the activated sludge process could only deal with a small fraction of the available material, and his thoughts turned more and more to the possibility of conserving nitrogen in Indian villages,” recounts Watson.

Other interests

After Fowler retired from IISc in 1924, he turned his attention to other subjects that interested him, though he continued to be an evangelist for the activated sludge process and composting. The titles of some of the articles he published after his retirement reveal the diversity of his interests: “The Multiplication of Scientific Societies”, “The Rights of Man”, “Land Management in the Punjab Foothills”, “Industrial Possibilities of Some Research Work Done in India”, “Arming for Peace”, “Energy and Economics”, and “The Relation of Universities and Scientific Institutes to Industrial Development”.

However, a topic that Fowler considered to be of vital importance, Watson writes, was currency reform. In an article titled “Chemistry and Currency” in Current Science, Fowler argued that existing currencies did not represent the true work carried out to earn them. He therefore proposed a new currency called ERN. According to the proposal, each ERN would be equivalent to 10 g of nitrogen in the form of protein, or alternatively 300 calories, the heat produced in the body by this amount of protein. “The value of a commodity would thus be its food value or the amount of work expended in its production,” explains Watson.

Fowler received many honours for his research, including being elected as a Fellow of the Royal Institute of Chemistry, the Chemical Society of England and the Royal Sanitary Institute. He was also chosen to be a member of the Industrial Research Council of the Government of India from 1937 to 1939.

Faith and country

Fowler was a devout Christian. Unlike many other scientists, he saw no conflict between religion and science. If anything, his faith seemed to motivate his research. “An ardent Christian Scientist,” Watson writes, “he [Fowler] was profoundly distressed by the waste of combined nitrogen and the resulting loss of foodstuffs and the lowering of the standard of living for the poorest of the poor.”

Even though Fowler did not explicitly write about his feelings towards India, his actions suggest that he felt a sense of belonging to his adopted country. He had been a regular visitor to India since 1906, ten years before he joined IISc. And when he did join the Institute in 1916, he chose to become a permanent resident of the country. After he moved to India, he favoured publishing in Indian journals – mostly in the Journal of the Indian Institute of Science during his active research career and Current Science, brought out by the Indian Academy of Sciences, after he retired. He and his wife Amy Hindmarsh decided to spend his post-retirement years in India (these were spent almost exclusively in Bangalore, except for two years between 1927 and 1929, when he was the Principal of Harcourt Butler Technological Institute in Kanpur).

Fowler also died in India – peacefully, according to Watson – on 21 March 1953 at the Central Hotel, Bangalore.